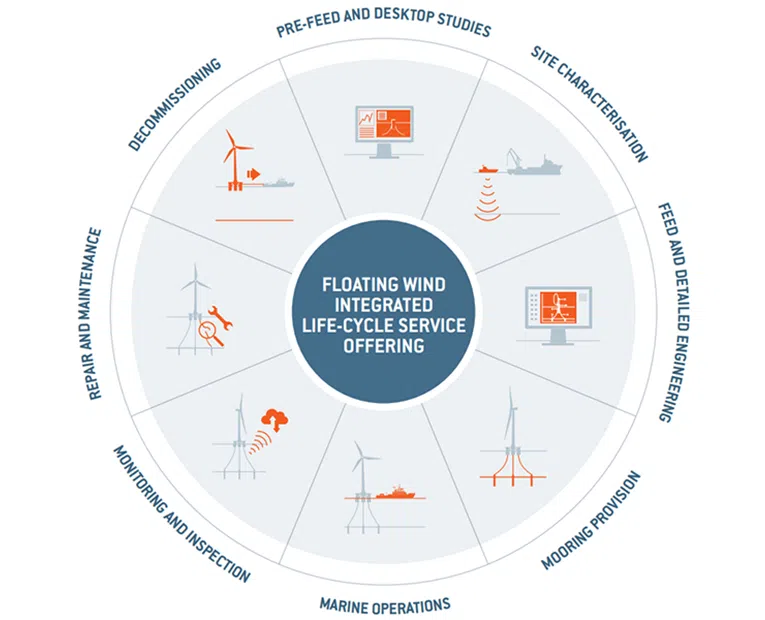

Acteon provides specialist support for the design, construction and installation of floating renewable energy projects.

Floating wind developments tend to be large and often complex projects that present significant technical challenges. Early involvement for all the project participants makes it easier to explore the available options and select the most efficient one.

At Acteon, we provide insights across areas such as anchoring, cable laying, installation methods, the mitigation of technical risks and lowering the levellised cost of energy (LCoE). Customers benefit from our pre-front-end engineering design and desktop studies; accurate evaluations of seabed characteristics; floating hull assessments; and advice in areas such as high-level mooring and cable arrangements, installation considerations and preliminary scheduling.

Our focus is always on finding innovative ways to reduce project footprints and overall costs.

This is possible through our profound, cross-disciplinary understanding and execution of design and engineering interactions across the project life cycle.

Watch our videoContact our experts

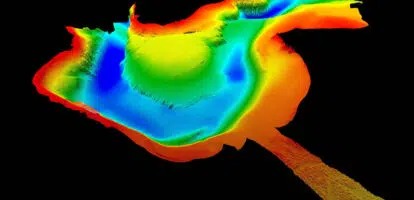

Our geophysical and geotechnical survey data teams work closely with our mooring experts to design floating wind foundations and anchors most efficient for the seabed conditions.

We have extensive experience of handling large assets, large volumes of mooring equipment and long cable lengths. This is invaluable when dealing with larger floating wind turbines.

Hull manufacturers and developers around the world have called on our longstanding expertise for front-end engineering, mooring feasibility, cable configuration, asset integrity and more. Check out our track record.

OPERATIONS, MAINTENANCE, AND INTEGRITY SERVICES

We provide a unique combination of services and in-house domain knowledge to ensure safe, efficient operations and enable the life extension of offshore wind infrastructure.

7 Challenges of Floating Wind

Cost and risk unpredictability

Cost and risk unpredictability

One challenge of installing floating wind farms will be to scale up projects from single to multiple units and still control costs. Contractors and offshore personnel need to have considerable experience in dealing with complex logistics and supply chain, towing large floating assets and performing multiple projects simultaneously.

Find out moreNext challenge

Supply chain and logistics

Supply chain and logistics

A 50-turbine floating wind farm could use 150 to 200 anchors and hundreds of kms of chain and fibre rope. Sourcing as well as storing and shipping such large volumes of equipment requires very specific knowledge and experience. While this could be a big strain on the supply chain, this challenge can be overcome by early design and early engagement. Established procurement agreements, a known supply chain, and a large mooring equipment inventory are a clear advantage.

Find out moreNext challenge

Maintenance

Maintenance

A proactive approach to monitoring and maintaining these structures through live data gathering systems incorporated throughout the life of the asset, along with engineered maintenance schedules, enable timely and informed integrity management decisions.

Find out moreNext challenge

Variability

Variability

Over 80 floating wind hull designs exist and conditions can be different from one area of the farm to another. Mooring engineers need to combine several variables to deliver an optimised design, from soil sample interpretation, metocean conditions, and environmental concerns, to dynamic cable constraints, supply chain availability, installation vessel availability and mooring loads.

Find out moreNext challenge

Cable safety

Cable safety

Coupled analysis of the floating wind platforms, accounting for both hydrodynamic and aerodynamic loading, ensures the array cable layouts be safely optimized and specifically engineered to withstand dynamic loads from harsh offshore environmental conditions.

Find out moreNext challenge

Structural integrity

Structural integrity

Ensuring the structural integrity of the floaters increases the lifetime of the assets, a key element in decreasing the LCOE (levelised cost of energy). It is important to define the perceived operational risk and required analytics before specifying and deploying the sensors. Digital twins are valuable tools to maintain the structural integrity of these structures.

Find out moreNext challenge

Challenging soil conditions

Challenging soil conditions

New areas identified as suitable for floating wind exhibit challenging soil conditions such as a rocky seabed or variable soil structure. Experience with all anchor types such as drilled and grouted anchors, driven piles, plate anchors and drag anchors as well as shared mooring options are necessary to deliver economic, safe and environmentally low-impact solutions.

Find out moreSolving your most pressing challenges

Acteon solution:

We have a deep cross-disciplinary understanding of the connections between key aspects of design and engineering across the life cycle of a project. We combine our mooring domain knowledge and advanced systems engineering expertise to run coupled analysis and develop compatible dynamic lazy wave cable configurations and mooring configurations.

Proof points

- Our ability to work on cable configuration design from the engineering phase all the way to logistics and installation allows us to bring significant economies of scale and cost efficiencies to the most complex projects.

- Recognising the need to work closely with our clients, Acteon’s advanced systems engineering segment, now has offices in many of the major offshore energy centres of the world, including London, Aberdeen, Paris, Houston, Kuala Lumpur, Rio de Janeiro, Perth and Beijing. Our offices are set up to enable seamless operation across all locations – efficiently sharing resources, capability and experience.

- With extensive experience in flexible risers and umbilicals, we can optimise array cable layouts for wind, wave, and tidal generators and produce detailed installation plans to ensure cables are installed safely and securely.

- We run advanced simulations, considering metocean data and mooring configurations.

Key projects and case studies

Acteon solution:

Floating wind solutions are particularly attractive in countries where shallow water areas coincide with poor seabed conditions (e.g., hard rock seabed), making bottom-fixed wind unfeasible. Anchoring floaters in such soils is particularly challenging. We provide the whole mooring package from front-end engineering and mooring design to anchor selection, fabrication, and installation. Our mooring experts team up with our geo-services and soil characterisation segment to define the best anchors suitable for the project.

Proof points

- With their extensive domain knowledge, our mooring specialists can help you decide on the most efficient anchoring solution for your project, from drag embedment anchors to SEPLAs and suction, drilled and driven piles.

- Our global network of shore bases can source or fabricate the right anchors for the job.

- Our engineers can advise on the advantages and disadvantages of utilising shared moorings or shared anchors as a cost-saving measure.

- We can provide designs that minimize mooring footprint and seabed contact.

Key projects and case studies

Acteon solution:

Designing a mooring system for a floating energy production system is complex and must encompass other factors than just metocean, soil and logistical elements. Turbine proximity for example to other turbines must be accounted for, as it affects energy production efficiency. The system’s interaction with other marine users and marine life must also be evaluated. Our engineers provide full support from conceptual engineering to detailed system design and installation procedures.

Proof points

- Our engineers can perform coupled analysis of floating wind platforms, accounting for both hydrodynamic and aerodynamic loading, to provide complex projects with an optimised design.

- Our engineering team has expert knowledge and experience in the design and installation of all anchor types and can help you decide what anchor type would be best for your application.

- Decoupling our activities from specific vessels means that we can propose creative, fit-for-purpose installation solutions that do not tie us to using a single vessel for all aspects of the work, and that allow us to enable the installation of bigger turbines at a lower cost.

Key projects and case studies

Acteon solution:

Even modest floating farm projects represent kilometres of chain and dozens of anchors. Logistical issues include where to procure the mooring equipment from, how to ensure its reliability, where to store it and how to get it offshore. Our engineers and offshore personnel have considerable experience dealing with complex logistics, moving multiple drilling rigs, and performing multiple projects simultaneously. We can leverage this practical experience to efficiently manage floating wind projects with hundreds of mooring lines. Our experience allows us to develop industrialised processes and installation procedures.

Proof points

- We leverage our purchasing power and knowledge of the mooring supply chain, to standardise component sizes and engineer the most efficient mooring systems.

- We maintain the world’s largest mooring equipment inventory and have deep supply chain knowledge. With shore bases in Brazil, Norway, Singapore, the UK and the USA near offshore locations, and an ability to leverage local supply chains, we can deliver the right equipment with shorter mobilisation times.

- Working with our vast supply chain and logistics providers, our engineers develop cost- and time- efficient procurement and logistic solutions to provide industrialised solutions for your development.

- For each project, we give you the choice to rent or purchase equipment to best fit your needs. We also fabricate tailored equipment. All our proprietary anchors can be designed, tailored, and fabricated to suit regional and project requirements.

Key projects and case studies

Acteon solution:

Ensuring the structural integrity of the floaters increases the lifetime of the assets, a key element in decreasing the LCOE (levelised cost of energy). Through early engagement and close collaboration with our clients, we join up various stages of the process and supply an end-to-end solution.

Proof points

- We start by defining the perceived operational risk or challenge moving through sensor specification and deployment, data acquisition and processing as well as our integrated cloud-based services including real-time analytics and visualisation.

- Acteon has been providing asset integrity solutions in the renewables market for over a decade with experience across the development of fixed offshore wind markets in Europe. With a comprehensive range of inspection, structural health, and balance of plant services, we can cover all your needs on a global basis.

- We integrate leading digital technologies to enable a remote and/or autonomous inspection, monitoring and installation service to reduce the need to send personnel offshore.

- Our digital platforms integrate into the client’s infrastructure, or we can supply data via our data portals or more bespoke networks.

Key projects and case studies

Acteon solution:

Our breadth of experience on temporary and permanent moorings of all sizes at all depths and in a variety of soils allows us to provide the necessary expertise to any floating wind project. We have supplied high-level procurement and installation cost comparisons as well as incorporated efficient installation procedures in our costing methods, reducing boat trips and POB.

Proof points

- Our mooring experts team up with our geo-services and soil characterisation segment to determine the best anchors suitable for the project.

- For installation, we strive to incorporate client equipment such as boats into our mooring designs and we have successfully used smaller anchor-handling vessels for permanent mooring installations.

- Our network of global bases allows us to source mooring equipment fabricated with local content.

Key projects and case studies

HARNESS THE POTENTIAL OF FLOATING WIND

Acteon’s expertise in mooring design and marine installation spans decades. We apply our deep domain expertise to help you choose the best options, from anchoring to cable laying to installation methods, to mitigate technical risks and lower the levellised cost of energy (LCOE).