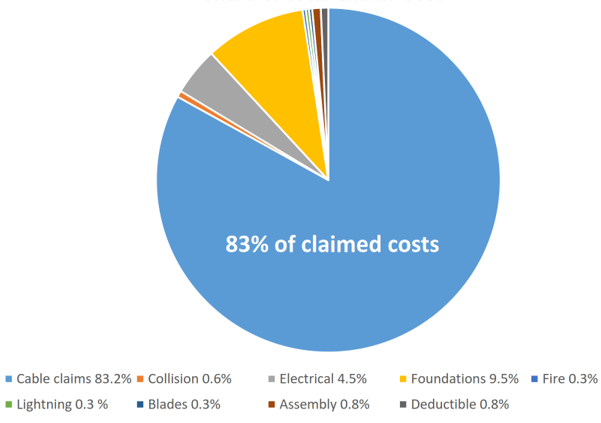

According to a 2019 study done by the University of Strathclyde, the average rate of power cable failure is approximately 0.003 failures/km/year for European wind farms. Considering a wind farm with 100km of power cable, there is a 30% chance of power cable failure in any given year. The average downtime for an inter-array cable repair is approximately 40 days and approximately 60 days for an export cable which significantly increases the LCOE due to energy generation losses and repair costs. On average, inter-array cable damage costs between $1.8M to $12M, and export cable damage costs between $10M to $30M.

Failure Rates of Offshore Wind Transmission Systems, 12 July 2019

According to Offshore Renewable Energy Catapult, the power cable failures can be categorised under four main groups with damage incurred during installation contributing to 46% of the failures, manufacturing defects accounting for 31% of failures, cable design 15%, and external effects when the power cable is in-place accounting for the remaining 8% of total failures.

The cable design includes cable components such as connectors, joints, and end terminations as well as the main conductor, insulation, and armor design. Poor design can cause localized hot spots and thermal expansion of the conductor. The continuous thermal expansion and contraction of the conductor harms the insulating layer causing microcracks which usually lead to partial discharges and consequently to a cable breakdown. The end terminations, field joints and interface locations usually host the cable stress hot spots where special attention must be given during cable design.

During manufacturing, imperfections can be introduced to the power cable that can lead to cable failures during operation such as voids and contaminations in the cable insulation, inadequate implementation and protrusions on the cable shields.

Power cables can undergo large local stresses during reeling and laying, as the installation activities can crush or pinch the power cable or introduce micro damages on the delicate components of the power such as the insulation and fibre optic. Special tools and techniques are usually required to protect the power cable during installation. In addition to local damage due to handling of the power cable, insufficient burial of the cable and installing the power cable outside the allowed weather windows or at a high vessel speed can also cause damage leading to power cable failures.

External damage usually covers the damage incurred during the in-place operation of the power cable such as damage caused by power cable movement on the rocky seabed without proper protection, scouring, and damage caused by the extreme wind, wave, current, and floating foundation motions.

Considering all the above, adequate design of the power cable system is essential to minimise the risk of in-place failures and the associated costs. Key design considerations that Acteon and their advanced systems engineering team can cover include the following:

- In-place design of the static and dynamic power cable to confirm suitability for extreme and long-term fatigue loading

- Detailed cross-sectional analysis of the power cable components

- Crushing analysis of the cross-section to confirm that loads during handling and installation operations do not compromise the power cable sheath

- Thermal analysis to confirm fitness for purpose

- Proper seabed layout, burial and protection design

- Installation design and analysis that leverages the in-field experience of Acteon’s offshore installation division

In order to maximise power cable reliability in an offshore wind farm, developers need to make sure that all aspects of the power cable design are thoroughly engineered, from manufacturing and installation to in-place conditions, and that risks are properly identified and addressed. At Acteon, we have expertise and experience to address all aspects of offshore power cables with our state-of-art engineering tools and practical field experience.

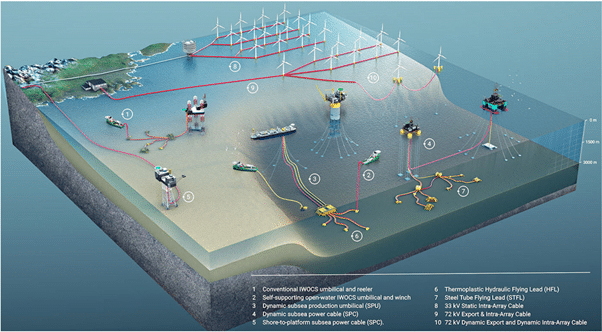

Acteon's renewable energy solutions brochure

Through early engagement and a unique point of contact, we can significantly reduce the total cost of construction and installation of subsea infrastructure, safely and responsibly. Gain access to exclusive content for complete renewable energy solutions.