Like any high-performance dynamic equipment, these structures will require engineered maintenance schedules. Acteon’s Asset Integrity and Monitoring segment takes a proactive approach to monitoring and maintaining these structures through live data gathering systems incorporated throughout the life of the asset, enabling timely and informed integrity management decisions. As we have learned in fixed wind applications, data capture is vital in technology assessment and development and as floating wind follows the fixed wind path to a lower levelized cost of energy, we must capture the insight to ensure maximum efficiency in this path to economic viability.

CREATING A TOP-TO-BOTTOM MONITORING PACKAGE

Each location has unique environmental variables which put their strains on the floating structures, moorings systems and cables. The key threats include:

- Cable integrity

- Structural degradation and fatigue damage

- Excessive corrosion

- Mooring failure

- Seabed scouring

- Mooring foundation integrity

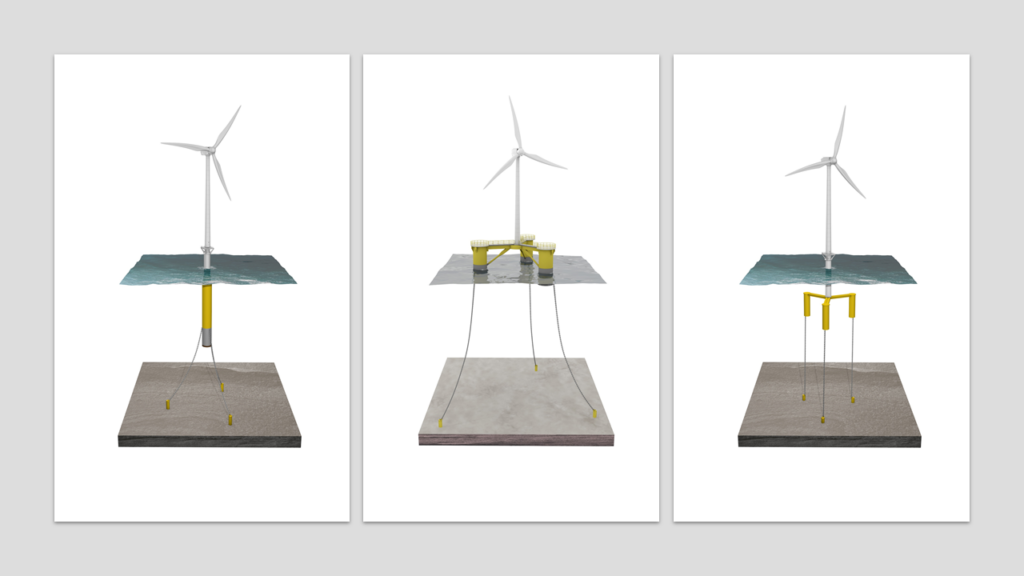

Capturing and reacting to these challenges is a vital part of maintaining and potentially extending the assets’ operational life. Minor changes in the equipment securing the floating platform to the seabed can have a detrimental impact on the turbine’s efficiency, for example, a small angular displacement at the level of the floating platform translates into a large linear movement at the highest point of the structure. If this is not controlled, it can damage and reduce the lifetime of the mechanical elements located in the nacelle. Therefore, creating a top-to-bottom monitoring package is imperative to ensuring the system is operating most efficiently. Acteon offers a range of services to ensure a full system monitoring package can be delivered, such as:

- Structural health and balance-of-plant services

- Corrosion and cathodic protection monitoring

- Metocean conditions monitoring

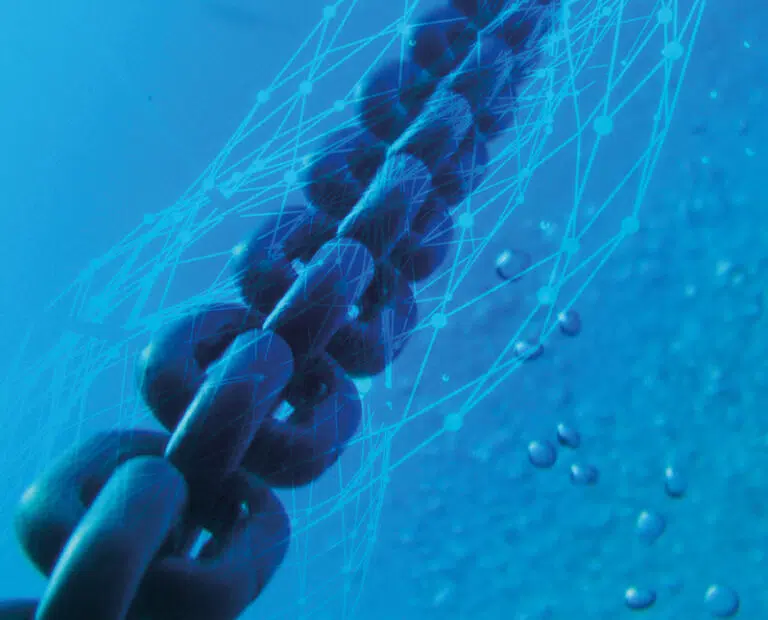

- Mooring chain inspection, maintenance and repair

- Inter array cable integrity monitoring

- Seabed survey

- Digital response twins and data orchestration

- Life extension remediation solutions.

With more productive locations for offshore wind energy production being identified further offshore, it is vital to learn from the structural dynamic response with a monitoring program that can be adjusted based on-site- or through technology-specific requirements. It is important to measure a range of primary and secondary dynamic responses across structures to understand how the asset is reacting to its environment in terms of fatigue, displacement, corrosion and more. The data can then be gathered and interpreted to ensure the inspection, repair and maintenance schedules are fit for purpose. This is an area that should be adjusted and developed now to ensure integrity monitoring can be standardised for a commercial-scale wind farm. Acteon leverages its significant experience in fixed offshore wind and floating energy structure installations to design, engineer and install equipment aimed at reducing project footprint while maintaining asset integrity through digitalisation and the use of engineering-based calibrated solutions such as digital twins.

In summary, floating wind structures must be designed, installed and monitored as a single system. Acteon’s segmented structure and breadth of services allow the customer to gain a full lifecycle approach in one location. Our in-house expertise in design, installation, operation, maintenance and decommissioning gives the client a unique perspective, not only considering a single part of the project but operating with the entire project lifecycle in mind.

HARNESS THE POTENTIAL OF FLOATING WIND

Acteon’s expertise in mooring design and marine installation spans decades. We apply our deep domain expertise to help you choose the best options, from anchoring to cable laying to installation methods, to mitigate technical risks and lower the levellised cost of energy (LCOE).