SUPPORTING CUSTOMERS WITH A RANGE OF O&M AND INTEGRITY SERVICES

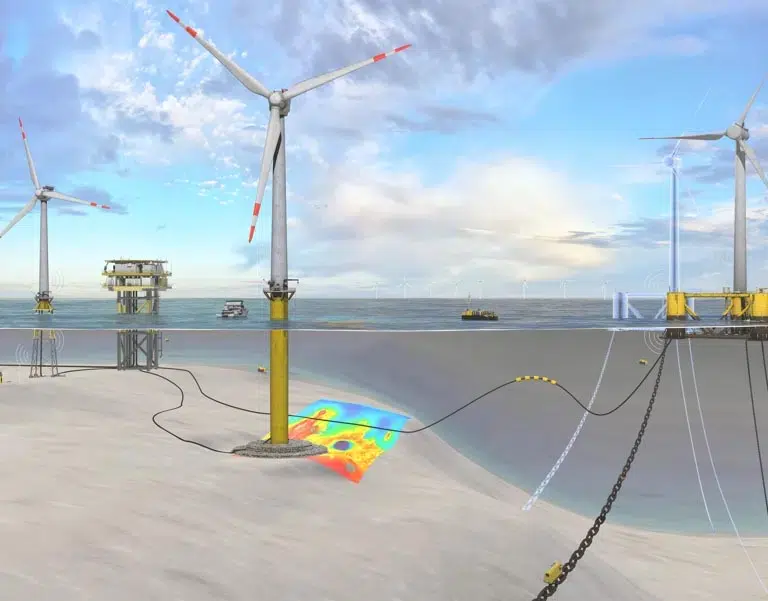

We help customers simplify processes and streamline operations by offering a single point of contact for subsea balance-of-plant operations and maintenance (O&M) and integrity services for fixed and floating wind farm developments.

- O&M Strategy development

- Scheduled inspection and survey services

- Structural monitoring and digital twin

- Data management and digital insight

- Anomaly assessment and engineering

- Remediation solutions

- Asset life extension

7 Challenges of O&M

Performing O&M in harsher conditions

Performing O&M in harsher conditions

Floating wind structures feature highly dynamic array cables and mooring systems and will experience significant wave, current and wind loading due to their remote location. Performing offshore subsea O&M activities at the sites could be time consuming due to the reduced weather windows. Historically used in the oil and gas sector, a holistic risk-based approach can be applied help optimise O&M activities. The approach comprises risk assessment, optimised spares management, monitoring, inspection, and the use of a digital twin to enable proactive maintenance. By adopting this approach, the frequency and duration of visits to distant offshore locations can be reduced while still maintaining an accurate picture of the condition of assets.

Next challenge

Data and insight management

Data and insight management

Several data management and visualisation services are available to help the operator manage the volume and frequency of data being collected through survey, monitoring, inspection, and digital twin technologies. Acteon’s iSite Subsea platform enables visualisation of large subsea inspection and survey data sets through a cloud-based solution. Data that was previously only available to users of specialist locally installed software applications is now available to all, enabling better collaboration and faster-informed decision-making. The management of such data sets over time is also efficiently handled, which is especially important given the life span of the assets.

Next challenge

Optimising survey and inspection

Optimising survey and inspection

A risk assessment process can be used to ascertain the type of information and frequency that should be gathered during operation. The necessary inspection, monitoring and maintenance tasks are then identified, and an associated schedule is set, helping to ensure that failures do not occur. The risk assessment is updated periodically during the life of the asset to reflect the actual performance and any degradation that has been identified. It can also be input into an optimised spares management strategy with a special focus on components like mooring systems and dynamic cables.

Next challenge

Maintaining structural integrity

Maintaining structural integrity

Sensors that have a low-power design and send data using advanced communications systems can be used to monitor carefully selected critical structural elements and help to provide a continuous long-term picture of their condition. Assets can be monitored to assess their state of structural fatigue and loading, the extent of corrosion, and general stability. Additional considerations for floating wind are the performance of any ballasting system, the moorings, and the dynamic cables. The data received can also be used to model the behaviour of the asset, which enables design verification and calibration of digital response twins.

Next challenge

Enabling life extension

Enabling life extension

The understanding of asset behavior, maintenance requirements and anomaly detection can be enhanced using digital response twin technology, which can accurately predict the structural performance and life extension of an entire wind farm using a minimal set of monitoring sensors. The digital twin is a near real-time dynamic virtual model that uses the inputs from the sensors to build a long-term picture of what normal, and abnormal, asset behavior looks like. The digital twin can be used to inform changes in inspection requirements with opportunities to optimise inspection frequency if the response is better than expected.

Next challenge

Managing multiple interfaces

Managing multiple interfaces

Working with a partner that can offer a range of O&M services gives a single point of contact and enables operators to be more strategic and proactive in their approach. Synergies can be realised in vessel logistics and having in-house integrity engineers and specialists as part of the team can help quickly address anomalies.

Next challenge

Reducing carbon footprint

Reducing carbon footprint

By leveraging low-logistics technologies such as uncrewed surface vessels (USVs) for survey and inspections, the operational costs, risk, and carbon footprint can be reduced. USVs can be used to deliver a combined survey and inspection scope to maximise in-field uptime while reducing mobilisation costs. This is supported by 3D visualisation tools to enable remote visualisation and data management of the asset while minimising offshore travel.

Solving your most pressing challenges

Acteon solution:

A unique combination of in-house domain knowledge and technical capabilities for subsea inspection and survey allows us to offer our clients an integrated solution for balance-of-plant O&M services.

Proof points

An extensive track record in mooring integrity management, inspection and replacement backs up our comprehensive in-house survey and inspection capabilities. We are the first provider to have executed a combined survey and inspection contract in the US market.

Key projects and case studies

Acteon solution:

USVs enable us to deliver a combined survey and inspection scope to maximise in-field uptime while reducing mobilisation costs. This is supported by the 3D data management visualisation Acteon tool iSITE to enable remote visualisation and data management of the asset while minimising offshore travel.

Proof points

We are the industry leader in seabed surveys with over 1,100 surveys completed worldwide, and we visualise and monitor over 50 assets through our iSITE platform. Optimised designs also use less steel.

Key projects and case studies

Acteon solution:

It is important to collaborate with us early in integrity and O&M. Our deep domain expertise helps our customers develop the most appropriate strategy for each wind farm to mitigate risks and lower the LCOE.

Proof points

We have delivered O&M strategy studies on several wind farms in Europe and the USA for fixed and floating wind and have engaged early with them to include bundled inspection and survey services in their strategy.

Key projects and case studies

Acteon solution:

We can offer surveys and inspections in several regions through our global company setup, and we use local resources to avoid transferring personnel around the world. Leveraging our global supply chain and working with local partners fulfills content requirements for our clients.

Proof point

We supported the first offshore wind cable inspection in Taiwan. On the Coastal Virginia Offshore Wind project operated by Dominion Energy, Acteon performed the inspection of the first offshore wind project in US federal waters. We are therefore the first provider to have executed a combined survey and inspection contract in the US market.

Key projects and case studies

Acteon solution:

Being vessel agnostic enables us to offer different logistical options, including using a vessel already contracted by the client. We also deliver data and insight through our in-house data management systems and platforms (iCUE and iSITE) to assist our clients and optimise their O&M schedules and decisions.

Proof point

Our Response Digital Twin solution enables complete oversight of the status of the asset to accurately plan and optimise inspection and maintenance activities. It creates a virtual mirror of the asset based on its real condition, thereby reducing the number of offshore trips for inspection.

Key projects and case studies

Acteon solution:

Our service includes an engineering assessment to identify the opportunities to extend the asset’s life or recommendations to enhance inspection and necessary remediation.

Proof point

We have an extensive track record in corrosion inspection. We replaced failed external anodes on the first offshore wind farm in 2004, and no other company has replaced cathodic protection on more offshore wind farms.

Key projects and case studies

Operations, maintenance and integrity services for offshore wind brochure

Discover the latest advances in logistics options and inspection technologies, using an approach to minimise downtime and maximise operational life, resulting in significant cost benefits.