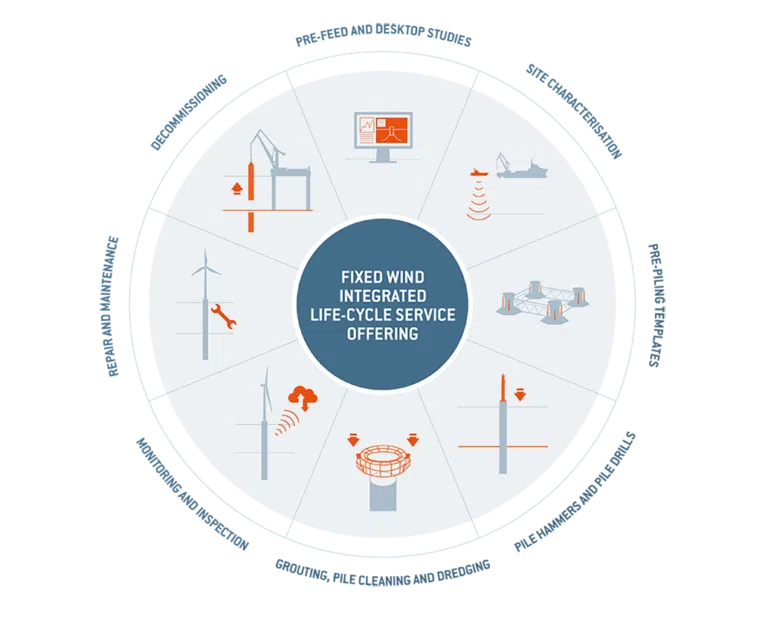

Acteon has installed more than 2500 foundations for offshore wind turbines over the past decade.

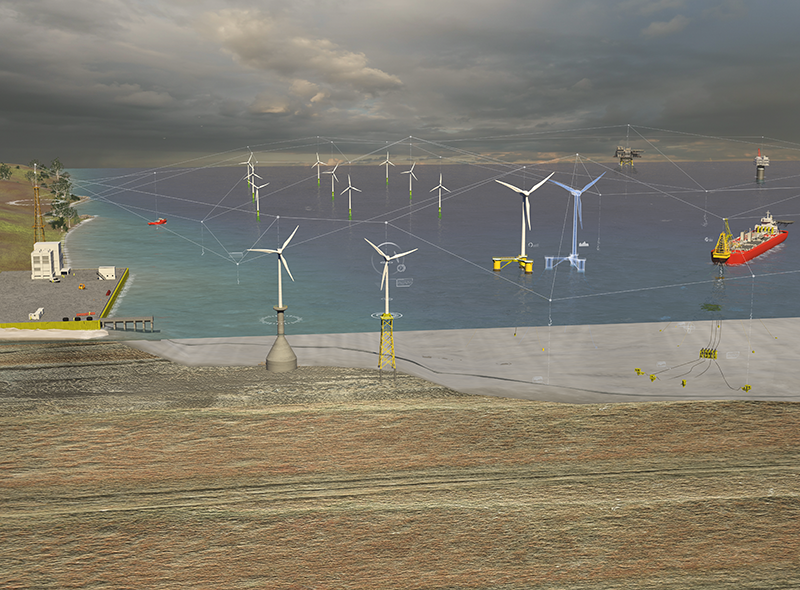

For bottom-fixed offshore wind energy projects, we integrate and manage:

- Surveying

- Engineering

- Lifting and handling

- Drilling

- Driving and grouting

This approach creates synergies and facilitates safe, timely and cost-effective delivery across all the phases of a development.

We are always seeking to streamline bottom-fixed wind energy tasks and to cut the carbon footprint associated with development work.

We do this in every phase of a project, from early stage geo-services through integrity management to decommissioning.

Larger turbine sizes present many potential issues including more underwater noise pollution during the installation phase. We provide the technology and solutions to mitigate piling noise and enable the installation of the next generation fixed bottom foundations.

The integration of geophysical and geotechnical surveys enhances efficiency and leads to higher quality data and, ultimately, a more accurate ground model for de-risked, more cost-effective structure designs.

By bringing Acteon in at the start of a fixed bottom foundation project, customers gain access to the widest scope of skills and expertise and can more easily achieve their project objectives.

OPERATIONS, MAINTENANCE, AND INTEGRITY SERVICES

We provide a unique combination of services and in-house domain knowledge to ensure safe, efficient operations and enable the life extension of offshore wind infrastructure.

7 Challenges of Fixed Wind

Cost of installation and maintenance

Cost of installation and maintenance

Developers need to find considerable cost savings on future projects if offshore wind is to remain competitive. Known operational methods should be applied to global offshore wind developments to create efficiencies, reduce OpEx costs and meet the challenges of larger foundations and difficult ground conditions. Through integration and working alongside specialist service providers, there is potential to reduce turbine downtime and operational costs while providing time- and cost-effective above-water and subsea operations, maintenance, inspection and survey work.

Find out moreNext challenge

Supply chain and logistics

Supply chain and logistics

Offshore wind is growing rapidly, driven by net-zero ambitions, particularly in northwest Europe and we are now seeing accelerated activity in new markets for example off the US East Coast and Taiwan. Many countries across the world have strict local-content requirements. The industry needs to create and grow local supply chains. Choosing a service company with a network of logistical bases and forming partnerships with local suppliers have clear advantages. Integration of services and leveraging local content can be used to reduce interfaces on a project and the number of personnel on board, as well as help to optimise the project timeline.

Find out moreNext challenge

Foundation concept evaluation

Foundation concept evaluation

Selecting a wind turbine foundation is a complex decision that must consider many factors, from fabrication, installation, operation and environmental impact, to the levelised cost of energy (LCOE) over the life cycle of the project. The screening process of fixed wind foundations is complex and requires research and expertise. A risk-based scoring matrix aiming for independence and transparency can be used to ensure that the most appropriate solution is reached. To achieve an accurate and thorough assessment, it is critical to understand the full life cycle by engaging with advanced systems engineers early in the planning process.

Find out moreNext challenge

Challenging soil conditions

Challenging soil conditions

Some soil conditions pose the risk of pile run occurrence, the uncontrolled penetration of a pile into the seabed due to unexpected, and reduced resistance from the sub-seabed soils. To help quantify and mitigate the risk of pile run, optimised data acquisition, intelligent engineering assessment, and robust installation methodologies can be applied. If in certain soil conditions the pile cannot penetrate through the seabed based on driving alone, the innovative drive-drill-drive method, also known as ‘3D’, has already been proven on European projects and could be applied to other global developments.

Find out moreNext challenge

Maintaining asset integrity

Maintaining asset integrity

A proactive approach to monitoring and maintaining structures through live data gathering systems incorporated throughout the life of the asset, along with engineered maintenance schedules, enables timely and informed integrity management decisions.

Find out moreNext challenge

Carbon footprint impact

Carbon footprint impact

One of the major impacts on the environment during pile driving is noise emission. Several countries, for example, Germany, have strict limits on the peak noise level as well as on the allowable installation time per pile for offshore wind projects. Noise mitigation technology can be applied to address the issue of noise emissions. Remote services and local content can also be applied to projects to reduce the number of mobilisations and personnel on board.

Next challenge

Large foundation sizes

Large foundation sizes

With the continuous drive for lower Levelised Cost of Energy (LCOE) and bigger wind turbines, monopile foundation sizes are expected to soon increase to 11 – 12 m bottom diameter. Foundation systems in which the pile, pile handling, drive-drilling system, and grouting systems are integrated with each other, and the installation vessel can be used to make XXXL monopile installation projects efficient and achievable.

Find out moreSolving your most pressing challenges

Acteon solution:

Getting Acteon’s experts involved early can help to reduce costs through optimising designs, reviewing constructability and identifying issues. We drive down the cost of wind farm installation with integrated engineering, lifting and handling, drilling, driving and grouting.

Proof points

- Optimising monopile designs for hammer properties and geotechnical conditions can reduce the installation noise, which enables more efficient driving and subsequently reduces installation time. Optimised designs also use less steel.

- Our drive-drill-drive solution is a combination of a drill and hammer and saves time and cost by negating the use of a temporary casing, grout or concrete and reduces the size, and associated cost, of the piling hammer.

- Our inventory spans a wide range of hammers, from 100 to 4400 kJ, which enables us to tailor to the specific needs of each project and maximise cost efficiencies. We can drive piles of any size at any water depth and select the optimal hammer, for example, we can drive a bigger hammer at 50% energy which is quieter than driving a smaller hammer at 100%.

- We have developed efficient monopile and transition piece upending and lifting equipment to optimise lifting sequences and reduce vessel time during installation.

Key projects and case studies

Acteon solution:

The MENCK noise reduction unit has become an integral part of the hammer during operations. MENCK is a marine foundations brand in Acteon’s Engineering, Moorings and Foundations division. By precisely influencing the force-generation characteristics of the single impact during piledriving, the unit reduces the noise-generating attributes of the impact while ensuring continuous drivability for the pile.

Proof points

- MENCK’s patented topside noise reduction skirt can reduce above water sound energy emission around a pile up to 65% – important for those projects close to noise sensitive areas.

- The noise mitigation system actively changes the force of character of the hammer to reduce the noise before it is transferred into the water. By changing the force character or force introduction time, MENCK has achieved a significant fatigue reduction on piledriving projects.

- Several hammer sizes in the inventory have the option of being used with the noise reduction unit. We implement a closed feedback loop for underwater noise where we check against the regional authority level and manipulate operational parameters of the hammer to reduce noise.

Key projects and case studies

Installation of 72 monopiles on Kriegers Flak windfarm in record time

Acteon solution:

Acteon’s asset monitoring systems provide real-time data, which enables remote asset performance monitoring resulting in reduced operational costs.

Proof points

- Acteon has designed and installed market-leading monitoring instrumentation on many offshore wind turbine foundations. This integrated digital solution includes comprehensive structural and corrosion monitoring.

- We offer a single source point of contact while packaging the entire solution combining multiple OEM equipment for the subsea balance of plant operations, maintenance and integrity services, providing complete subsea surveillance for fixed wind farm developments.

- Our NX2 integrated digital platform allows us to hold the data to perform predictive analysis and digital twinning of the asset.

- We offer digital twinning as part of an integrated digital solution, to identify real-time issues as well as build a longer-term picture of the structural health of the turbines

Key projects and case studies

Wind farm foundations benefit from precise monitoring during settlement phase

Acteon solution:

Acteon’s deep domain experience in asset integrity and corrosion protection systems enables it to solve existing problems and future-proof assets.

Proof points

- Whether it is corrosion prevention or remote monitoring equipment, Acteon has provided and installed the tools to ensure the integrity of many ageing assets worldwide.

- We have developed a proprietary software platform (NX2) that gathers, stores and translates structural monitoring data into critical insight to optimise operations throughout the lifecycle.

- We can apply grout to ageing assets for life extension purposes. This can be used to address damage or degradation to offshore structures.

- We provide a range of marine growth removal (MGR) tools for cleaning marine fouling from structures. The MGR systems can remove both hard and soft fouling, subsea and topside throughout the operational life of a turbine.

Key projects and case studies

Retrobuoys installed on German offshore windfarm to replace failing anodes

Acteon solution:

We deliver expert services for the installation of offshore wind foundations of any size, at any water depth.

Proof points

- We provide global analysis combined with foundation hammer/drill co-engineering and environmental assessment to increase cost efficiency and establish a more industrialised way of delivering fixed renewables projects.

- We integrate surveying, engineering, lifting and handling, drilling, driving and grouting, and manage all of these through a single interface.

- Our extensive project history demonstrates our expert support across the life cycle of wind farm project development. We have over a decade of global experience with fixed renewables projects and a track record of installing more than 2,500 foundations.

- We have worked with the largest operators on the most technically complex projects.

Key projects and case studies

Integrated solution for installation of over 300 piles on major wind farm

Acteon solution:

We are always seeking to streamline fixed renewable energy operations and to minimise the carbon footprint associated with development work. We do this in every phase of a project, from early-stage geo-services through to integrity management and eventual decommissioning.

Proof points

- Our focus on this area started with the development of hydraulic piledriving solutions, as alternatives to diesel hammers, to improve factors such as noise level and the efficiency of the energy and blow rate.

- To gather geophysical and geotechnical data, we deploy unmanned surface vessels and use remote access and data processing to reduce the number of vessel days and personnel on board.

- We provide local resources in key activity hubs, including crew, support functions and in-region servicing to help optimise projects.

- We minimise mobilisations by using satellite-based remote connectivity which allows engineers to view the hammer operation in real-time as well as see exactly what the on-site technicians are seeing through a VR headset. This avoids the need to mobilise additional expert engineering resources, contributing to the overall uptime of the kit.

Key projects and case studies

Doubling survey capabilities accelerates wind project operations

PEOPLE TALK ABOUT A MORE SUSTAINABLE FUTURE

At Acteon, we are proud to deliver proven and innovative marine solutions for the offshore renewable energy industry. In an ever changing and growing renewables market, we are evolving to meet escalating industry demand by integrating scalable solutions for every phase of the bottom fixed project lifecycle.