In this blog, Tim Eyles, Vice President, Acteon, explains how a risk-based holistic approach can reduce operation and maintenance (O&M) costs, improve long-term margins, and extend asset life for floating wind installations.

The global offshore floating wind market is set to expand, and with this, there will be numerous challenges and risks for operators pursuing new projects. According to one research study, floating wind capacity is forecast to reach more than 25 GW by the middle of the next decade, from just under 60 MW today.

What is the rationale for a holistic approach to operation and maintenance?

Historically used in the oil and gas sector, a holistic risk-based approach is preferable for the large concrete or steel structures proposed for floating wind. These structures are moored or anchored to the seabed using multiple components, they experience significant wave, current and wind loading, and feature highly dynamic array cables. The approach comprises risk assessment, optimised spares management, monitoring, inspection and the use of a digital twin to enable proactive maintenance.

By adopting this approach, the frequency and duration of visits to distant offshore locations can be reduced while still maintaining an accurate picture of the condition of assets. The approach reduces the cost of ownership and, ultimately, through maintaining an operating history, enables the life extension of the asset.

How can risk assessment be used to drive inspection schedules?

The risk assessment process can be used to ascertain the type of information that should be gathered about the structure during operation, and at what frequency. This is achieved by considering critical design aspects, including corrosion, fatigue and wear, and assessing the failure mechanism, speed of failure, frequency and consequences. The necessary inspection, monitoring and maintenance tasks are then identified, and an associated schedule is set, helping to ensure that such failures do not occur.

The risk assessment is updated periodically during the life of the asset to reflect the actual performance and any degradation that has been identified. The risk assessment can also be input into an optimised spares management strategy with special focus on components like mooring systems and dynamic cables.

How can the intelligent use of monitoring and inspection data be used to predict the structural performance and life extension of a wind farm?

The understanding of floating asset behaviour, maintenance requirements and anomaly detection is further enhanced using digital response twin technology, which can accurately predict the structural performance and life extension of an entire wind farm using a minimal set of monitoring sensors.

The digital twin is a near real-time dynamic virtual model that uses the inputs from the sensors to build a long-term picture of what normal, and abnormal, asset behaviour looks like. Findings from physical inspections, for example, loss of steel thickness or increases in marine growth, can also be input into the model. The digital twin can then be used to inform changes in inspection requirements with opportunities to decrease inspection frequency if the response is better than expected. Similarly, rapid intervention can be made if abnormal behaviour is spotted thus avoiding more costly failures.

How can data and insight be effectively managed?

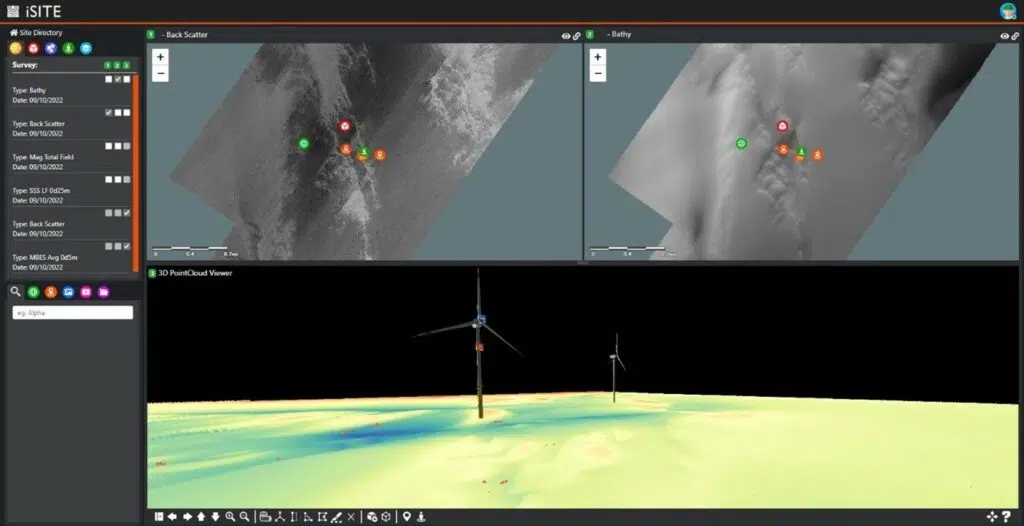

A key challenge could be managing the volume and frequency of data being collected through monitoring, inspection and digital twin technologies. However, there are several data management and visualisation services available to help the operator manage O&M. For example, Acteon now provides software such as iSite Subsea from UTEC, a geo-services brand in Acteon’s Data and Robotics division, that enables visualisation of large subsea inspection and survey data sets through a cloud-hosted solution.

Data that was previously only available to users of specialist locally installed software applications are now available to all, which enables better collaboration and faster-informed decision-making. The management of such data sets over time is also efficiently handled, which is especially important given the life span of the assets being managed.

What are the overall benefits for floating, and fixed, wind farm operators?

In summary, a risk-based holistic O&M strategy combines symbiotic disciplines with the aim of reducing O&M costs and extending asset life. These include risk assessment, motion, structural and cable monitoring, digital twin technology, optimised inspection and surveys, and maintenance and spares management. By leveraging low-logistics technologies such as uncrewed surface vessels (USVs) for survey and inspections, the operational costs, risk and carbon footprint can be further reduced. Using inspection, survey and monitoring data, engineers can perform structural assessments to better understand critical risks and make recommendations on remedial solutions to help prolong the life of the asset.

Having a single point of contact for all subsea O&M activities enables operators to be more strategic and proactive in their approach, and provides opportunities to simplify processes, streamline operations and improve the profitability of the floating wind farm.

Furthermore, the same process can be applied to larger fixed wind farms, particularly where the assets are in mid to late life.

The original full article was featured in PES Wind and can be accessed here.

Operations, maintenance and integrity services for offshore wind brochure

Discover the latest advances in logistics options and inspection technologies, using an approach to minimise downtime and maximise operational life, resulting in significant cost benefits.