Q: WHAT TYPES OF MOORING SYSTEMS ARE GENERALLY CONSIDERED?

A: There are two types of mooring systems:

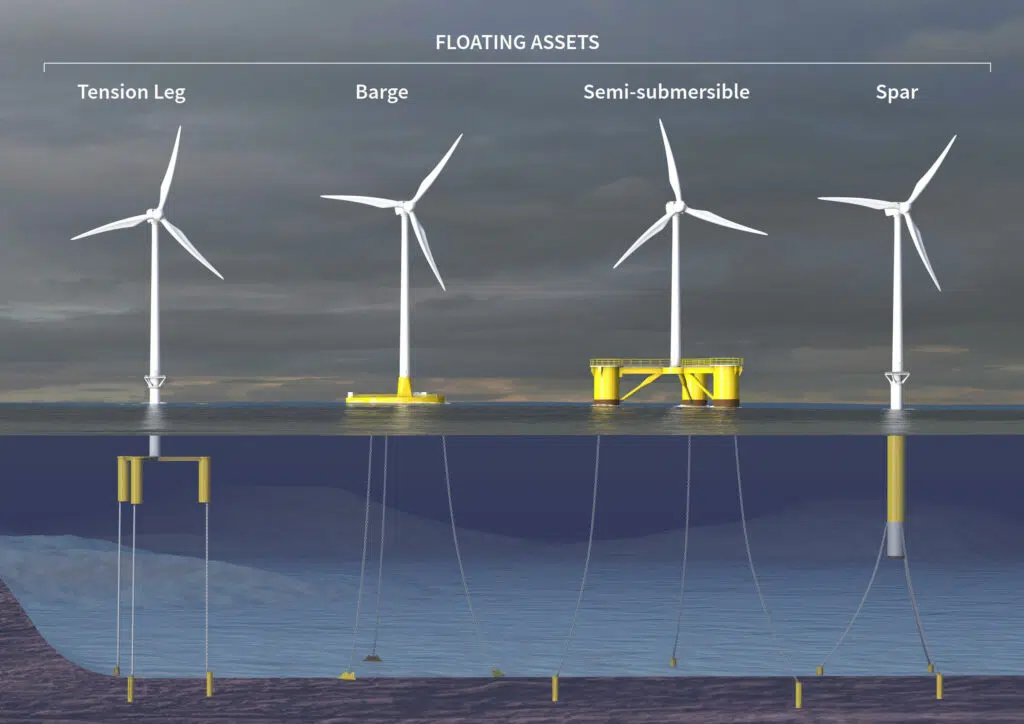

- Tension leg systems are commonly used to moor Tension-Leg Platform (TLP) structures, where they are held in place with vertical tendons that are typically anchored with driven piles that penetrate deeply into the seabed. Deeply driven piles are used to counteract high tension loads in which the vertical component of tension is the largest contributor.

- Spread mooring systems with catenary, semi-taut, or taut lines are often used to moor monohull, semisubmersible, and spar structures. These systems are commonly anchored with drag embedment or suction pile anchors and mooring lines comprised of chain, spiral strand wire, and polyester or other synthetic rope components. Spread moorings are dominated by horizontal tension loads on which they rely to minimize the vessel’s horizontal response to wind, waves and current.

Recent floating wind activity involving a floating spar-like structure will be moored by catenary lines. The Hywind Project in Scotland, which consists of five 6 MW turbines, uses suction anchors and a ballasted catenary layout with three mooring cables and 60-tonne weights hanging from the midpoint of each to provide additional tension.

Q: AS FLOATING WIND PROJECTS DEVELOP, ARE NOVEL SOLUTIONS INVESTIGATED?

A: Yes, novel solutions are also being investigated as the floating wind industry grows. Many concepts and ideas are being pursued to develop different anchoring devices and mooring configurations. Check out our Flexibly Embedded Plate Anchor research & development work.

Other kinds of mooring line components are also being researched, developed and tested. Low stiffness synthetic lines like nylon are being augmented and constructed in ways that make them more fatigue-resistant to accommodate long design lives. Traditional mooring components are being combined in varying ways to achieve composite stiffnesses that achieve preferred station-keeping performance characteristics. Mechanical devices that offer a more compact way of providing design specific stiffness characteristics and load monitoring capability are also being developed.

Regarding installation, new and innovative mooring installation methods and techniques are being evaluated to maximize economies of scale that come with arrays of multiple floaters moored together or near each other. Off-vessel tensioning devices and techniques are also created to minimize the capital expenditure associated with the housing and installation of winches and fairleaders on the floater and to facilitate long-term mooring maintenance and repair work with minimal operational expense. Methods and products that can be installed in shorter amounts of time are also being developed. Saving a short amount of time on a given operation can translate into large savings on commercial wind farms as that operation may take place hundreds of times during a campaign.

With their solid mooring track record including some of the most complex offshore projects in the world, InterMoor and the whole Acteon Group are well placed to apply their extensive domain knowledge to the growing floating offshore wind sector.

This article was originally featured in Energy Global.

HARNESS THE POTENTIAL OF FLOATING WIND

At Acteon, we know that smart technology and innovation are the key to reduce projects footprints, risk and overall costs.

We leverage our profound, cross-disciplinary understanding and execution of design and engineering interactions across the project life cycle to come up with innovative and creative solutions to the most complex projects.