Anchors

Return to Moorings & AnchorsSearch products

X Products selected

Search products

X Products selected

This is the only drag embedment anchor capable of accepting directional changes of loading from all headings. After installation, the Bruce Omni-Directional Dennla can embed in the rearward direction as well as the forward direction by veering into alignment with the direction of loading.

Application: Mobile & Permanent moorings

Seabeds: Sands, clays, muds

Mooring: Catenary, Semi-taut leg & taut leg

Advantage: Ultra deep water anchor that accepts directional load changing

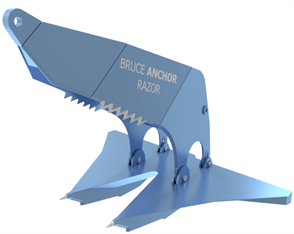

The Bruce GP has a further increased fluke area from that of the Bruce PM, and the shank straightened to enable mass to be redistributed to the fluke for higher holding capacity and a lower rearwards recovery load.

Application: Mobile & Permanent moorings

Seabeds: Sands, clays, muds

Mooring: Catenary & Semi-taut leg

Advantage: Highest holding capacity of any anchor available on the market today (size for size)

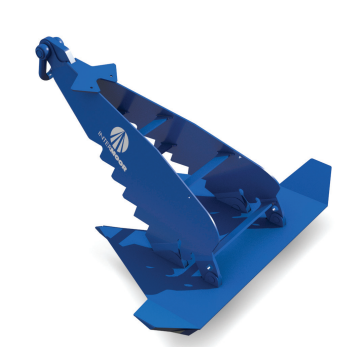

With increased holding capacity and the cranked shank design, the Bruce PM is the perfect anchor for permanent mooring requirements and hard bottom conditions.

Application: Mobile & Permanent moorings

Seabeds: Sand, Clays, muds

Mooring: Catenary & Semi-taut leg

Advantage: Cranked shank reduces seabed penetration resistance

Developed in 1986, the Bruce FFTS Mk4 anchor is still one of the only drag embedment anchors available on the market that completely satisfies the HHP anchor rules regarding self righting as set out by DNV GL.

Application: Mobile & Permanent moorings

Seabeds: Sands, clays, muds

Mooring: Catenary & semi-taut leg

Advantage: Self-righting

InterMoor’s SEPLA system uses a suction follower (similar to a suction anchor) to embed a plate anchor deeply in the soil. The suction follower is retracted once the plate anchor is brought to design soil depth and can be used again and again to install additional plate anchors.

SEPLA anchors are more efficient geotechnically than the suction anchors used most often to offset significant vertical loads. Whereas a large part of a suction pile’s structure is unused after installation, the SEPLA plate anchor is fully embedded in deeper, higher strength soil layers, with all components actively resisting the mooring loads.

Because they utilise a suction follower, SEPLA anchors are classified as direct embedment anchors. This means the precise location and depth of the anchor is known (whereas location and depth of drag-embedded anchors can only be estimated). In congested fields, where a clear area to drag in an anchor may not exist, SEPLA is the ideal solution.

SEPLA anchors are used for both temporary and permanent moorings (i.e. drilling rigs and production facilities).