Pumps and Water Jetters

Return to ROV ToolingSearch products

X Products selected

Acteon Equipment sales & rental Electronics & Tooling ROV ToolingPumps and Water Jetters

Search products

X Products selected

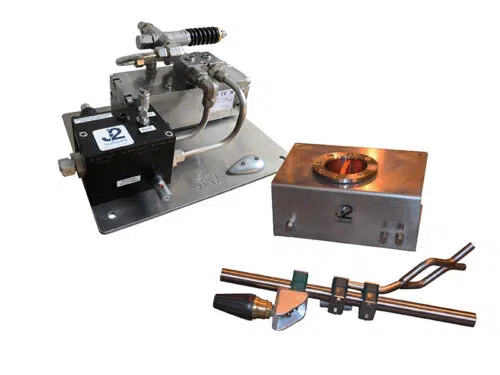

The CaviBlaster 0858 cleans the surface of any underwater structure using the energy released by the implosion of the bubbles during the cavitation process. When directed at the surface being cleaned, the energy released by the collapsing bubbles causes marine growth to be removed from the surface.

The CaviBlaster 0858 can be supplied with a 3 way manipulator operated valve and standard 400bar rated turbo nozzle allowing the operator to change between nozzle types without need to recover the ROV to surface or alternatively can be supplied as just a nozzle allowing use with a HPW520 jetter already installed on the ROV.

The CaviBlaster 1030-ROV high-pressure water power unit allows the operator to use the water flow and pressure to generate cavitation at the end of the proprietary nozzle.

The CaviBlaster cleans the surface of any underwater structure using the energy released by the implosion of the bubbles during the cavitation process. When directed at the surface being cleaned, the energy released by the collapsing bubbles causes marine growth to be removed from the surface.

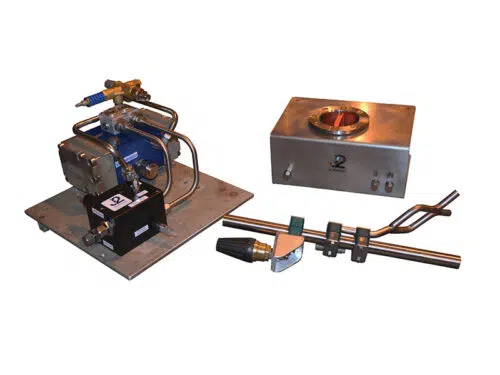

The CaviBlaster 1331 cleans the surface of any underwater structure using the energy released by the implosion of the bubbles during the cavitation process.

When directed at the surface being cleaned, the energy released by the collapsing bubbles causes marine growth to be removed from the surface.

The Caviblaster 1331 can be supplied with a 3 way manipulator operated valve and standard turbo nozzle allowing the operator to change between nozzle types without need to recover the ROV to surface.

The CaviBlaster CLK140/44 cleans the surface of any underwater structure using the energy released by the implosion of the bubbles during the cavitation process.

When directed at the surface being cleaned, the energy released by the collapsing bubbles causes marine growth to be removed from the surface.

The unit can be supplied with either a zero thrust balanced gun for diver use or a 50:50 thrust ROV lance for use with small electric ROV’s.

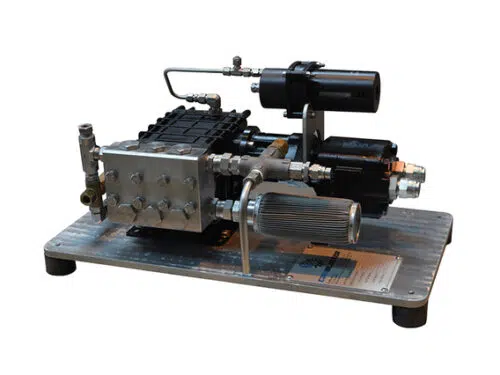

The Harben pump system is based around the 8 piston P-type pump fitted with a hydraulic drive motor and is capable of an output of 59LPM @ 345 Bar.

The HLK-31020 Water Jet, has been developed to assist in cleaning tasks needed on many subsea structures before intervention.

Driven by a 3 phase motor, the pump can deliver 12.5 litres per minute at 110 BAR, through an orbital nozzle.

The nozzle can be deployed by a manipulator or fixed on the ROV and directed by the ROV itself. The water jet is supplied with a stainless steel filter and an over pressure relief valve.

The unit is based around the 400-1.75 and 1.2 neron intensifier and is capable of supplying pressures up to 5000 PSI when used for fluid injection tasks.

The unit is based around the 400-1.75 and 1.2 neron intensifier and is capable of supplying pressures up to 5000 PSI when used for fluid injection tasks.

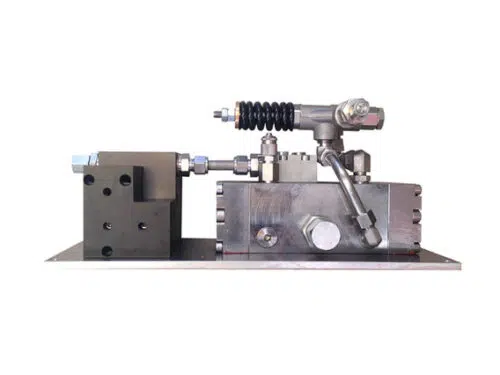

The High pressure jetter is based around the Dynaset HPW pump and is capable of jetting at 400Bar with the standard nozzle fitted.

The system is supplied with all input valves and secondary side unloader valve, hoses for connection to ROV, lance hose, manipulator handle and turbo nozzle.

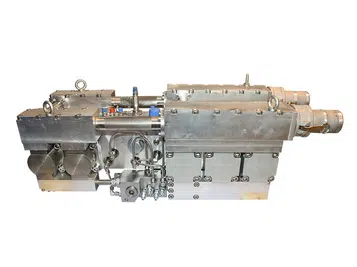

The 510 Intervention Pump is top of its class in the market on BOP Intervention for secondary emergency ROV Intervention.

All hydraulics and most of the water pipes have been converted to compact bolted manifolds increasing reliability and with minimal maintenance preventing downtime occurrence. The pump-set consists of two independent pumping stages.

Both stages are designed to be switched automatically and can also be switched manually if required. This new design massively increases the reliability of the system. The Hi pressure pump controlling system has 4 levels of pressure. The required pressure is pre-set on deck and the switch over between pressure levels are controlled remotely via the ROV hydraulic controlling system.

The controlling system provides an option to prevent the shear of the tool passing through the BOP in case of starting the pump by mistake by a ROV operator. This solution can be fitted to this pump set to operate more BOPs by a variable operating pressure during a single subsea mission.

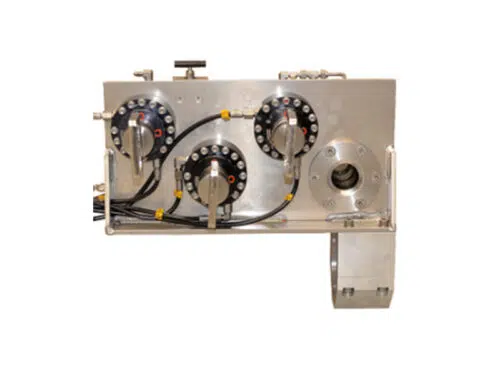

The Specialist Offshore Services’ double block and bleed panel is meant for use in pressure testing subsea assets.

Specialist Offshore Services provides a double block valve arrangement with a 3rd valve added. As a result, this allows the user to vent the pressure from between the valves. Thus giving the user the ability to use accepted subsea procedures in pressure testing. The panel designed by Specialist Offshore Services turns out to be a major time saver as there are no manip operations required. This is due to 1/4 turn rotary actuators controlling the 1/4 turn valves when connected to the ROV hydraulics. Each valve requires the use of an ROV Solenoid to open and close it. The units are customisable for different working pressures without changing the 1/4 turn actuator.

The unit can be mounted on a underslung or rear mounted skid or any other custom location. Pictured is the unit designed with secondary ability to use a manip if required as a secondary means of operation. Therefore the unit must be mounted within reach of the 7F Manipulator. The pictured is for attachment to the Schilling 5F Manipulators, but the unit could be placed in the skid drawer.

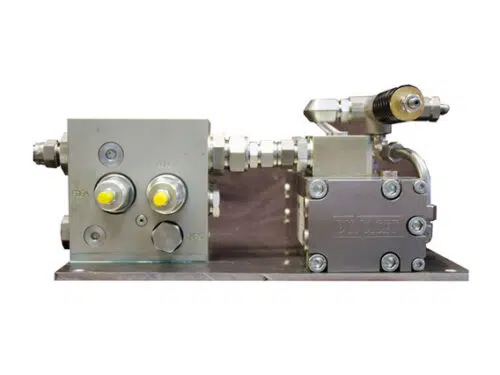

Industry standard Jetting system, with proven reliability with impressive pumping capabilities. No other system offers the same power and reliability.

This unit capable of up to 420 bar output. Suitable for connection to any Subea reservoir via the ¾” BSPP suction port, capable of pumping water, seawater, hydraulic oil, methanol or glycol for use as %luid injection. Simple to interface with incorporated custom drive manifold means that the unit can be used on a wider range of ROV’s, as it allows the user to limit Pressures and flows depending on the customers hydraulic supply abilities. Unit is supplied complete with hydraulic hoses, and turbo nozzles.

Industry standard Jetting system, reliable with impressive pumping capabilities. No other system offers the same power and reliability.

This unit capable of 520 Bar. Suitable for connection to any Subea reservoir via the ¾” BSPP suction port, capable of pumping water, seawater, hydraulic oil, methanol or glycol. Simple to interface with incorporated custom drive manifold means that the unit can be used on a wider range of ROV’s, as it allows the user to limit Pressures and flows depending on the customers hydraulic supply abilities. Unit is supplied complete with hydraulic hoses, and turbo nozzles.

The Tritech AnchorZip 10 is a unique product which has been developed using the highly successful ZipPump and ZipJet technologies.

The AnchorZip 10 is a heavy duty suction anchorpump designed for workclass vehicles able to produce 25hp of hydraulic power. The AZ10 will offer a very quick and cost effective way of installing and removing suction anchors. Output pressures may be regulated to ensure that differential pressures remain within the structural limits of all types of suction anchor.

The Tritech Super ZipJet ROV Dredge Pump replaces the successful Tritech ZipJet Ultra range of suction & jetting systems.

The Super ZipJet pump incorporates many technical advances over the previous generation of ROV suction and jetting systems. These advances are a direct result of customer feedback.

Considerable emphasis has been placed on increasing the pumps efficiency in both the suction and jetting modes. The Super ZipJet pump incorporates several design features which improve its reliability and substantially reduce its maintenance costs.

The Super ZipJet pump will not block or jam because there are no moving parts on the dredging side of the system. Power is derived from a stream of high velocity fluid creating a low pressure region behind the suction nozzle. The pump may be rapidly switched from suction to jetting mode.