IHPU / DWP & Accessories

Return to ROV ToolingSearch products

X Products selected

Acteon Equipment sales & rental Electronics & Tooling ROV ToolingIHPU / DWP & Accessories

Search products

X Products selected

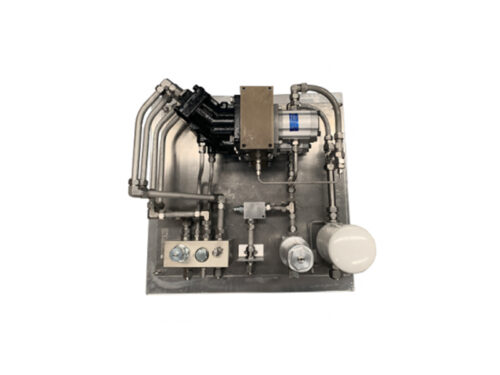

The fixed displacement DWP / IHPU is based around a fixed displacement motor driving a fixed displacement pump via an oil-filled bell housing.

The fixed displacement DWP / IHPU is based around a fixed displacement motor driving a fixed displacement pump via an oil-filled bell housing.

Fitted to the input of the motor is a control block offering flow/pressure and pilot on/off control. On the secondary side the output of the pump is connected to a pressure filter and a cetop 5 DCV C/W relief valve, the return from the DCV passes through a return filter prior to return to the secondary reservoir.

The 10 litre Kystdesign compensator is a positive pressure compensator manufactured from anodised aluminium.

The 10 litre Kystdesign compensator is a positive pressure compensator manufactured from anodised aluminium.

Fitted with a polycarbonate lid, it allows for visual inspection of the fluid, an optional analogue sensor allows remote monitoring of the fluid volume.

The 16 litre KystDesign compensator is a positive pressure compensator manufactured from anodised aluminium.

The 16 litre KystDesign compensator is a positive pressure compensator manufactured from anodised aluminium.

Fitted with a polycarbonate lid, it allows for visual inspection of the fluid, an optional analogue sensor allows remote monitoring of the fluid volume.

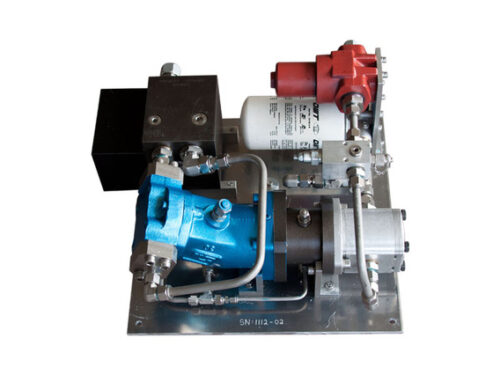

The Specialist Offshore Services dirty oil pack allows the user peace of mind when using tools that typically contaminate the ROV’s hydraulics.

The Dirty Work Pack (DWP) uses a reliable bent axis piston motor on the input side, or clean oil side. Coupled to this, via a compensated housing, is a proven gear pump. The gear pumps have proven reliable to normally unacceptable levels of contaminants, and generally give warning of imminent failure by the pressure slowly dropping. Catastrophic failure is rare with gear pump, limiting possible contamination.

The gear pump was chosen to be easily replaceable, and cost effective on the client. Each new job sees the unit shipped with a new pump. To ensure protection of the pump, is a low pressure filter element, meeting the minimum specifications of the pump. On the output of the pump is a high pressure filter, which is used to ensure that should the unit be pushed past it’s operating envelope, the users equipment is protected.

Driving the unit is a custom manifold, specifically made to minimise fittings, setting up and installation time. The manifold also allows the user to lower flow specifications should the user need to couple it to a certain sized hydraulic specification, and still meet pressure requirements.

The dirty oil pack allows the user peace of mind when using tools that typically contaminate the ROV’s hydraulics.

The dirty oil pack allows the user peace of mind when using tools that typically contaminate the ROV’s hydraulics. The Specialist Offshore Services Dirty Work Pack (DWP) uses a reliable bent axis piston motor on the input side, or clean oil side. Coupled to this, via a compensated housing, is a proven gear pump. The gear pumps have proven reliable to normally unacceptable levels of contaminants. The gear pump has been chosen to be easily replaceable, and cost effective. Each new job see’s the unit shipped with a new output pump. To ensure protection of the pump is a low pressure filter element, meeting the minimum specifications of the pump. On the output of the pump is a HP filter, which again is used to ensure that should the unit be pushed past it’s operating envelope, the users equipment is protected. Driving the unit is a custom manifold, specifically made to minimize fittings and setting up/installation time of the unit which also allows the user to lower flow specifications should the user need to couple it to a certain sized hydraulic specification.

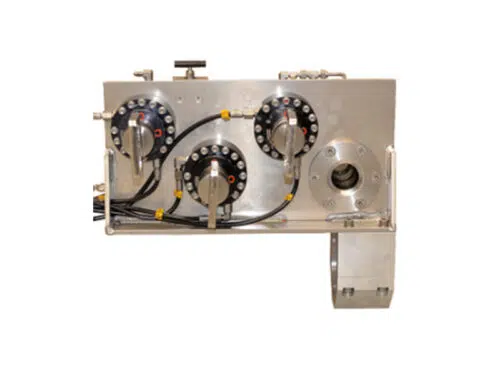

The Specialist Offshore Services’ double block and bleed panel is meant for use in pressure testing subsea assets.

Specialist Offshore Services provides a double block valve arrangement with a 3rd valve added. As a result, this allows the user to vent the pressure from between the valves. Thus giving the user the ability to use accepted subsea procedures in pressure testing. The panel designed by Specialist Offshore Services turns out to be a major time saver as there are no manip operations required. This is due to 1/4 turn rotary actuators controlling the 1/4 turn valves when connected to the ROV hydraulics. Each valve requires the use of an ROV Solenoid to open and close it. The units are customisable for different working pressures without changing the 1/4 turn actuator.

The unit can be mounted on a underslung or rear mounted skid or any other custom location. Pictured is the unit designed with secondary ability to use a manip if required as a secondary means of operation. Therefore the unit must be mounted within reach of the 7F Manipulator. The pictured is for attachment to the Schilling 5F Manipulators, but the unit could be placed in the skid drawer.

The Specialist Offshore Services 220bar IHPU/Fluid Injection system is a compact and integrated all-in-one unit based on the reliable and highly regarded Dynaset HPW pump.

Simple to interface with incorporated custom drive manifold means that the unit can be used on a wider range of ROV’s, as it allows the user to limit pressures and flows depending on the customers hydraulic supply abilities. Unit is supplied complete with hydraulic hoses. No other system offers the same power and reliability.

The Specialist Offshore Services ROV Fluid Injection Systems can be underslung skids or compact backpack mounted, integrated all-in-one units.

The company has many years of experience in using subsea fluid injection systems and integrating these to various ROV systems. In combining these subsea pressure systems with Pressure & Temperature logging systems we provide reliable and robust high tech full solutions.

The Specialist Offshore Services subsea LP pump is a Hypro centrifugal pump. Hypro Series 9300 hydraulic motor-driven centrifugal pumps provide smooth performance. The 150psi pump can be conveniently mounted on to the ROV, thus becoming part of the vehicle’s hydraulic system.

Designed for pumping fluids, Polypropylene centrifugal pumps may also be used to pump acidic and other highly corrosive liquids. Contact Specialist Offshore Services if more information on the ROV LP Pump is required.

On/ Off control of hydraulic supply to the pump, including adjustment of flow and pressure has been integrated by Specialist Offshore Services into a custom designed manifold.

The Hypro “close-coupled” design reduces the mounting space required, so that it eliminates long shafts and couplers between the pump and motor. The pumping fluid is taken directly from the surrounding seawater.

The LP Pump can be set up to provide suction for items such as suction grippers.

Another option is that the ROV LP pump can also be used in conjunction with one or more of the Specialist Offshore Services hydraulic rotary actuators in order to provide low pressure back seal testing, double block and bleed or hotstab port selection, or precise control of LP fluid injection quantities.

The isolated dual directional control valve (DCV) is used to add functionality to the dirty work pack (DWP), to allow it to control 2 extra functions. These 2 extra funcions, are controlled by the ROV clean oil solenoids, but are isolated from the DWP oil paths.

The valve block has reverse free flow checks, allowing the unit to connect to cylinders and not interrupt the flow back to tank.

The only setup required of the system is to set the SCCA cartridges to the required pressures. There are no other setting required on the panel. The DCCC-XYN valves require a minimum of 500psi to shift the spool on the pilot ports. The ports can take up to 3000psi.

Supplied on a job by job basis, this panel is normally customised to suit a client specification.