IMPORTANCE OF OPTIMISED DATA ACQUISITION

Building a solid understanding of soil conditions begins with quality data acquisition. Although the experience of nearby sites can be referenced to identify potential risks, site-specific data is essential to identify the risk of a location specific pile run occurrence.

Geophysical data is acquired and interpreted to develop a targeted geotechnical site investigation campaign. Sourcing a provider who can deliver all the geo-services elements of a project assists in minimising risk by improving continuity of data, operational schedule, and the building of a detailed knowledge base.

We always recommend having location specific in situ testing data (i.e., PCPT data) and soil sample data beyond the foundation depth of influence. Onshore laboratory testing of acquired samples provides further information to determine the engineering characteristics of the soil.

CHARACTERISING AND ASSESSING THE RISK THROUGH INTELLIGENT ENGINEERING

Characterising the risk

Before being able to assess the risk of pile run occurrence, the soil, and available data sources, including historic and offset data, are assessed, and interpreted. Driving data from previously driven piles can be used to develop site specific driving resistance models and/or calibrate standard driving methodologies.

Collating and summarising this data into an integrated ground model provides a complete overview of the site that can be interrogated. Our geotechnical engineers may develop the ground model in a geospatial information system (GIS) and develop a foundation hazard register (FHR) to detail ground risk, both for in-place and installation performance, specific to the proposed foundation solution.

Assessing the risk

Once the available data has been reviewed, the pile installation assessment(s) is undertaken. This typically comprises self-weight penetration (SWP) analysis, pile stability analysis, assessment of driveability and risk of pile run occurrence.

The SWP estimates the penetration of the pile, assuming the weight of the pile, as well as the weight of the pile and hammer assembly. The stability analysis determines the required penetration when the pile can safely support itself and the pile gripper can be removed.

Using recognised industry and site-specific methodologies combined with available historical records enables a soil resistance to driving (SRD) model to be developed. Using the SRD within software that models the one-dimensional elastic stress wave travelling through the pile, a profile of blow count versus depth is determined. This allows the optimal hammer size to be selected and confirms that the piles can reach target penetration.

When will pile run be initiated?

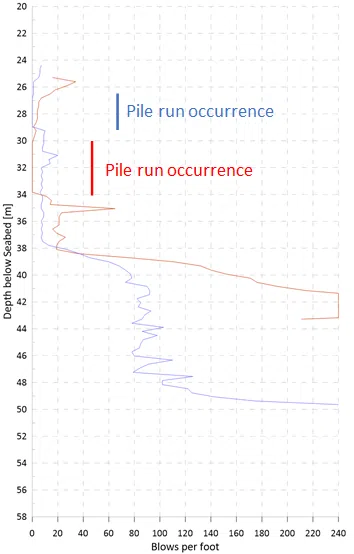

Pile run will occur when the soil resistance, cannot support the weight of the pile and hammer assembly. A serious pile run will happen when the soil resistance is constant or decreases with depth after a pile run is initiated. The potential risk of pile run occurrence, along with the likely depth of initiation and length of pile run can be assessed. The illustration below shows two cases where pile run occurred during the installation of steel tubulars offshore.

MITIGATING RISK THROUGH ROBUST INSTALLATION SOLUTIONS

Robust installation solutions are devised to minimise and mitigate the risk of pile run. Based on the installation assessment, location-specific driving plans are developed in conjunction with the hammer provider, detailing geotechnical installation risk at each location along with recommendations relating to hammer operation.

Solutions delivered by Acteon, include optimisation of the stability frame design to provide support during installation. During the installation phase, our offshore engineers can provide immediate assistance and guidance, thus improving schedule efficiency.

OPTIMISED SOLUTIONS TO INCREASE COMMERCIAL VALUE

Engaging early with our customers allows us to identify the specific challenges of their project and allows us to develop an efficient strategy to approach the risks associated with the proposed foundation solution. This, along with our extensive in-house knowledge and experience allows us to meet or improve development schedules and mitigate commercial risk.

The services offered by Acteon are underpinned by our consultancy capability, allowing us to leverage the combined installation experience across the Acteon business segments and brands including, MENCK, LDD, 2H and Claxton.

FIXED RENEWABLES CASE STUDY PACK

The case studies in this brochure demonstrate Acteon’s global capability to provide proven and innovative marine solutions for the offshore renewable energy industry.