QUICKLY AND EFFICIENTLY PLACE CEMENT IN THE ANNULUS BETWEEN THE CONDUCTOR PIPE AND THE OPEN-HOLE SECTION AT THE POINT OF INSTALLATION TO ACHIEVE OFFSHORE CONDUCTOR INTEGRITY.

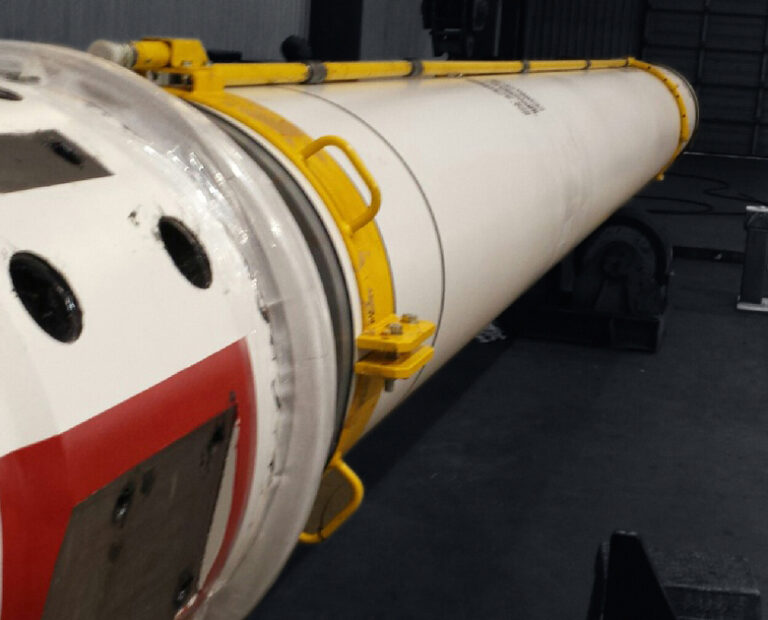

Ensure conductor integrity with the conductor cement top-up system. A proven and reliable back-up to primary cementing, the system injects cement into the annulus between the conductor pipe and the open-hole section at predefined locations. Our conductor cement top-up system is also regularly used to overcome the issues associated with poor formation conditions.

Conductor cement top-up systems are typically required for the following seabed conditions:

- ‘Soft soil’ conditions

- Coning effects at the seabed

- Irregular formations or ‘washouts’.

The system consists of a cementing line attached to the conductor which is then run together to the required depth. The line is terminated with a spreader which introduces the cement at the base of the problem area when pumping commences. Some designs include multiple cement outlets at different depths.

Delivered by Claxton

Claxton combines a fast-track design and project engineering service with a large rapid call-off inventory to deliver integrated end-to-end life of field solutions for customers' renewable and oil and gas energy projects all around the world.

Integrate this product

Acteon can also offer an integrated project management service. This involves managing the activities of one or more of our companies on a customer’s behalf and providing a single point of contact for all aspects of project management.

DRILLING AND DECOMMISSIONING SERVICES - REQUEST MORE INFORMATION

Acteon’s expertise in drilling and decommissioning spans decades and covers the full lifecycle of a project from the acquisition of subsea information and data, to bespoke drilling packages to onshore disposal and recycling.

Similar products and services

-

High pressure (HP) and ultra-high pressure (UHP) pumps are an integral part of the...

-

To complement our extensive rental fleet of risers, we also offer a large range of...

-

Product and service line brand, Claxton, has successfully developed and deployed SWAT...

-

Integral with other Acteon decommissioning equipment, WellRaizer benefits from a modular...