SUPPORTING A CHANGING OIL AND GAS INDUSTRY

Our services integrate:

- Pre-development and front-end-engineering

- Development offshore drilling services

- Foundations and moorings

- Production asset installation

- Integrity monitoring and management

- Asset life extension and decommissioning

This breadth of skills enables us to provide customers with support throughout the life of field and reduce project footprint while minimising environmental impact.

WE DELIVER TIME AND COST EFFICIENCIES ON LARGE AND COMPLEX PROJECTS IN ALL WATER DEPTHS.

Life-of-field management maximises cost efficiencies, which covers geotechnical services, structural design, regulatory approval, procurement, fabrication, installation, and decommissioning.

Installations in deeper water and ageing assets present various challenges that require innovative solutions and streamlined operations to ensure project success. Our expert engineers excel at navigating the entire project lifecycle working in partnership with the customer to meet their goals.

We leverage local content to help us provide a strong platform for delivering commercial benefits. This includes optimising supply chains so that we can deliver excellence wherever we operate. Being vessel-independent further minimises costs and package deck footprint.

We understand that most oil and gas assets were not designed with decommissioning in mind. With regulatory challenges varying by location costs need to be minimised. We strive to optimise and reduce the time, cost, and risk of decommissioning operations through our rigless approach to well abandonments.

OPERATIONS, MAINTENANCE, AND INTEGRITY SERVICES

We provide a unique combination of services and in-house domain knowledge to ensure safe, efficient operations and enable the life extension of offshore oil and gas infrastructure.

Solving your most pressing challenges

Acteon solution:

Through Acteon’s independently operated brand 2H, we provide expert guidance on permitting to simplify and expedite the regulatory process. We have a strong track record of helping customers secure project permits in the most stringent regulatory environments, both onshore and offshore. Working with various stakeholders, from regulatory authorities to public interest groups, we help clients navigate and expedite complex regulatory processes. We also ensure that all operations including piling meet regional legislation.

Proof points:

- 2H California is regularly commissioned by the California State Lands Commission to perform well re-abandonments.

- MENCK developed a solution to address the challenges of environmental noise by designing ‘primary’ noise mitigation systems. These systems are integrated into the hammer and change the force character of the hammer to reduce the noise before it is transferred into the water.

- We use digital solutions allowing the engineer at home or remote location to plan offshore works, undergo site familiarisation, inspection, and maintenance identification all without having to go offshore.

- We have an extensive network of over 100 locations in more than 20 countries, allowing us to leverage local expertise at any time.

Read the case study: Unconventional well reabandonment approach | 2H Offshore

Acteon solution:

Acteon provides a single interface for the seamless delivery of drilling support services, from project management and surveying to mooring and riser system engineering, supply, installation. This minimises project time, cost and drilling risk.

Proof points:

- We simplify rig moving and station-keeping by providing a service that includes site survey, on-board towmasters and mooring and riser design through to procurement and offshore installation.

- Being independent of vessel providers allows to us source the most efficient vessel for the task, which minimises costs and package deck footprint.

- 2,000+ piles driven globally.

- 1,600+ onshore and offshore conductor and pile installation projects completed.

Read the case study: https://acteon.com/case-studies/turnkey-survey-solution-for-challenging-black-sea-development/

Acteon solution:

Acteon has decades of experience providing engineering, project management and offshore installation delivery for the most complex projects in congested seabed environments.

Proof points:

- Our SEPLA anchor combines two proven anchoring concepts – suction piles and plate anchors – to increase the anchor point efficiency of pre-set moorings. It improves embedment precision, and geotechnical efficiency and reduces mooring system costs for floating structures.

- Acteon provides a full design, fabrication and installation service for suction piles, providing a single interface for the life cycle of the project.

Read our Suction pile track record

Acteon solution:

As far as installing platforms and exploration-production vessels in deep and ultra-deep water, Acteon was one of the precursors and has established several industry records in waters up to 9,400ft. (2,890m). To provide seamless project management, efficient engineering and offshore delivery services, Acteon develops project-specific installation aids, methods and procedures.

Proof points:

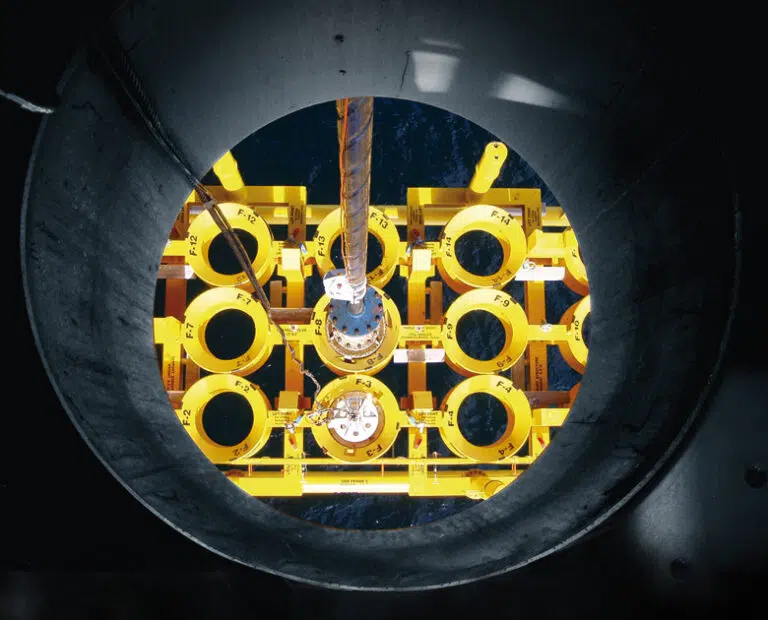

- Acteon has remained at the forefront of construction and foundation innovation, as the only company worldwide to offer a full conductor installation service in deepwater – currently being used for some of the largest ultra-deepwater projects in the world. We install conductors by driving them to the desired penetration with a MENCK-built deepwater subsea hydraulic hammer spread. The spread allows these services to be provided in water depths up to 7,300 ft. with +/- 3-inch elevation accuracy.

- Deep water riser and flowline integrity management programmes from Acteon can also maximise production uptime.

- We completed the installation of the seven anchor mooring piles for a CALM Buoy, drilling from a DSCV in water depths over 270m.

- We provided positioning technology on a world-class ultra-deep water field development project in Africa, with depths exceeding 2,000m.

Read the case study: UTEC operates new iXblue subsea positioning technology on challenging ultra-deep water construction project – Acteon

Acteon solution:

Acteon’s customisable and integrated installation and positioning solutions reduce the risk of cost overruns, expedite floating facility installation and increase lifetime value. Our single interface prevents simultaneous operations and avoids schedule conflicts between contractors.

Proof points:

- We have worked on some of the world’s largest and most complex oil and gas developments.

- Our track record of developing cost-effective solutions for complex marine operations is second to none. We have proven experience in some of the world’s most challenging environments. We have conducted studies and offshore operations in both hemispheres, in both shallow and deep-water conditions, and in all types of weather. We have moved and moored semi-submersibles, jack-ups, Tender Assist Drilling (TAD) units, drillships, and barges in all soil conditions, using either chartered vessels or client-prescribed vessels.

- We have a wealth of experience in anchor and pile design that enables us to select the most suitable options from a range of proprietary infrastructure products that includes conventional anchors, driven- and suction-piles and our patented Suction Embedded Plate Anchor (SEPLA), all of which we fabricate and install.

- We offer integrated services on innovative or flexible terms and conditions that some operators may find attractive: for example, by delivering all services under a single comprehensive contract or providing many scopes of work under a master services agreement.

Read the case study: https://acteon.com/case-studies/two-fpsos-one-campaign/

Acteon solution:

We evaluate and determine the cause of production decline and advise improvements and solutions for extending well life and ultimate recovery. This provides good returns on the incremental investment in remedial measures required to prolong well life.

Proof points:

- We have drilled, completed, side-tracked, reworked, stimulated, or abandoned more than 2500 wells.

- Our market-leading design, modelling and analysis software is used to support geographical geological modelling, well trajectory planning, tubular analysis and the economic analysis of different scenarios.

- We are proficient in over 25 different engineering software packages to characterise the geology, integrity, economics and details of our projects.

- We have completed projects in over 30 different countries.

Read more: https://acteon.com/specialisms/asset-life-extension/

Acteon solution:

As oil and gas fields around the world mature, operators are faced with the decommissioning of their offshore assets. At Acteon, we understand that most of these assets were not designed with decommissioning in mind, that regulatory challenges vary by location, and that costs need to be minimised.

Proof points:

- We strive to optimise and reduce the time, cost, and risk of decommissioning operations through our rigless approach to well abandonments. Combining our innovative equipment, including the patented SABRE™ and SWAT™ tools, bespoke expert engineering and skilled personnel also allows us to focus on efficiencies while performing quality work.

- We have an extensive track record of efficiently and safely decommissioning all types of floating facilities, from risers to calm buoys to entire platforms.

- Using our well abandonment services, remedial experience, and floating facilities removal expertise, we also help operators restore the subsea marine environment.

- Over 100 subsea wells cut globally, and successful cuts in up to 300m water depth.

Read the case study: https://acteon.com/case-studies/a-well-severance-solution-for-three-subsea-tieback-wells-and-eight-dual-bore-wells/

FLOATING FACILITY INSTALLATION SUPPORT BUYERS GUIDE

It goes without saying that oil and gas field operators expect their floating facilities to be installed safely, on time and within budget. They also welcome increased efficiencies, seamless project management and efficient data integration. Download this e-book for optimised lifetime station-keeping solutions that serve oil and gas fields in any water depth.