Close Menu

- Acteon Home

- Industries

- Divisions

- Products & Services

- Integrated Solutions

- About Acteon

- Contact us

Search products

X Products selected

No matter how much raw data has been collected from the survey site, it’s the results that your client values. When budgets get tighter, survey tasks become ever more time-critical and the process of interpreting acquired data must be as quick and easy as possible.

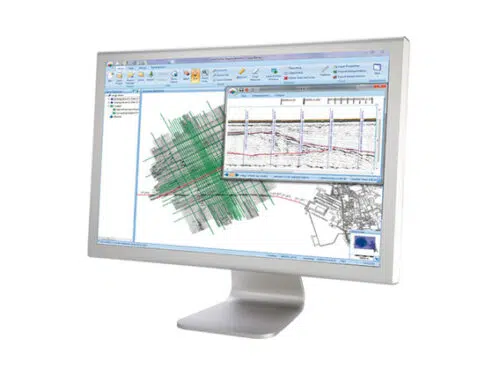

Coda GeoSurvey Productivity Suite integrates the tasks of analysing, tagging and mosaicing complex data sets – thereby ensuring faster and more precise results.

With Coda GeoSurvey running on multiple workstations with remote networked data storage, high volumes of geophysical data can be managed and processed quickly, maximising productivity.

Survey Engine Seismic+ is a ‘next generation’ 2D seismic data processing, interpretation and reporting application for the marine survey industry.

Built on the years of experience that have made CodaOctopus’ software solutions a market leader at the heart of geophysical operations worldwide, Seismic+ brings survey tools up-to-date with the latest database and GIS technology. Based around a flexible database, Survey Engine gives fast access to all survey information, even from the largest data sets. As a result, Seismic+ offers exceptional time-saving advantages when reviewing data and performing interpretation. Designed with thousands of line kilometres of survey data in mind, we believe that Survey Engine Seismic+ is the most productive and intuitive tool available for seismic data processing, interpretation and reporting.

Seismic+ integrates fully with Sidescan+ so that both sidescan and seismic data sets can be used in the same project yielding interpretation productivity benefits.

MDL’s Fanbeam® system is a laser based positioning sensor designed for repetitive, high accuracy range and bearing measurements from offshore support vessels and other marine structures.

The system is primarily used as a dynamic positioning (DP) reference sensor measuring the position of an offshore support vessel (OSV) relative to an offshore structure such as a platform. Using the position data from the Fanbeam and other sensors, the DP system automatically holds the vessel on station allowing operations to take place. The system is regularly used as the primary position reference during critical short-range operations such as cargo container lifts from platform supply vessels.

The system has also been extensively used for seismic source positioning relative to geophysical exploration vessels and for positioning mine detection equipment relative to navy vessels.

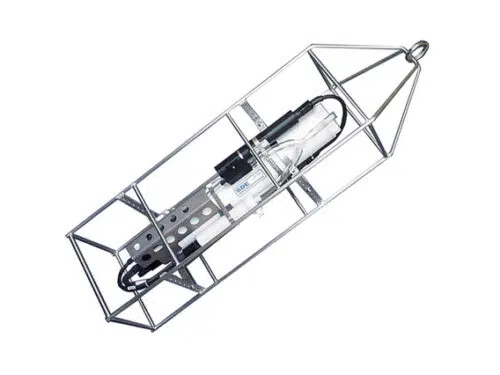

The SBE 19plus V2 (Version 2) SeaCAT Profiler measures conductivity, temperature, and pressure (depth) and provides high accuracy and resolution, reliability, and ease-of-use for a wide range of research, monitoring, and engineering applications. The pump-controlled, TC-ducted flow configuration minimizes salinity spiking caused by ship heave and allows for slow descent rates without slowing sensor responses, improving dynamic accuracy and resolving small scale structure in the water column.

Compared to the previous 19plus, the V2 incorporates an electronics upgrade and additional features, with six differentially amplified A/D input channels, one RS-232 data input channel, and 64 MB FLASH memory. An optional Digiquartz® pressure sensor provides highest-accuracy pressure measurement. Data can be output in XML as well as ASCII and HEX formats. Firmware upgrades can be downloaded through the communications port, without opening the instrument.

The 19plus V2 samples continuously at up to 4 scans per second (4 Hz) (2 Hz with Digiquartz®), is battery-powered and self-recording, and is commonly used in the field without a computer, recording up to 1000 individual profiles. Data can be uploaded and processed later, as well as transmitted to a PC in real time for acquisition and display using Seasoft software provided (cable length dependent on number of auxiliary sensors, sampling and baud rate, and cable properties). The 19plus V2 can supply power to 7 external sensors and log their outputs with each CTD scan. Nine D-size alkaline batteries provide up to 60 hours of continuous operation when logging C, T, and P at 4 Hz.

The 19plus V2 is easily integrated with an SBE 32 Carousel Water Sampler and is ideal for integration with the SBE 55 ECO Water Sampler. Both real-time and autonomous auto-fire operations are possible with any Sea-Bird CTD / Water Sampler system.

In moored mode, the 19plus V2 records time series measurements at user-programmable intervals (10 seconds to 4 hours). Moored mode is easily configured with setup commands and by removing the profiling T-C Duct and installing optional anti-foulant devices. (If profiling not needed, the 16plus V2 SeaCAT Recorder offers greater moored-mode flexibility.)

CONFIGURATION, OPTIONS, AND ACCESSORIES

A standard SBE 19plus V2 is supplied with plastic housing for depths to 600 meters, strain-gauge pressure sensor, 64 Mbyte FLASH RAM memory, alkaline batteries, glass-reinforced epoxy bulkhead connectors, SBE 5M miniature pump with plastic housing, and T-C Duct.

Options and accessories include:

SOFTWARE

The SBE 19plus V2 is supplied with a powerful Windows 2000/XP software package, Seasoft©V2, which includes programs for communication and data retrieval, real-time data acquisition and display, and data processing (filtering, aligning, averaging) and plotting.