Access exclusive content

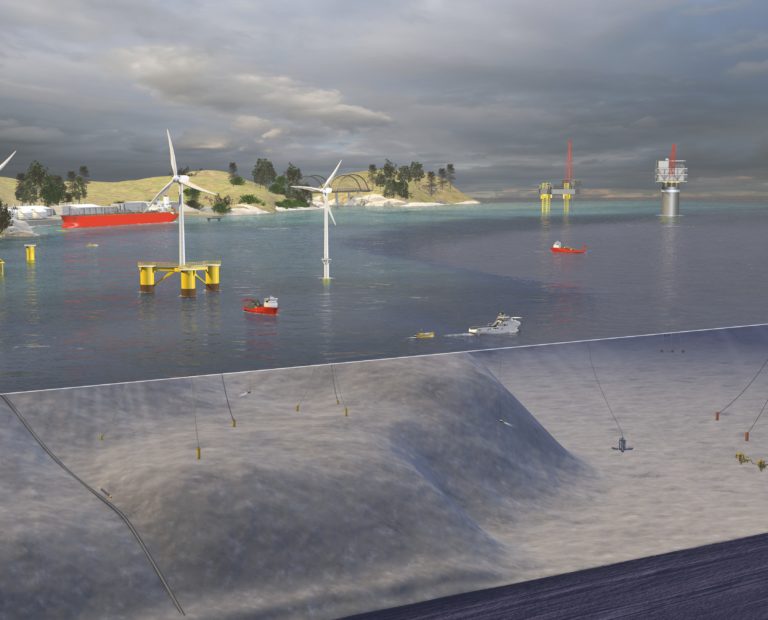

GEO-SERVICES BROCHURE

We are transforming data into critical insight driving key design and construction decisions.

Discover more about our solutions to real customer challenges and explore our full range of services to help you achieve project efficiencies.