1. SELECT A PROVEN SOLUTION DESIGNED WITH QUALITY DATA COLLECTION IN MIND

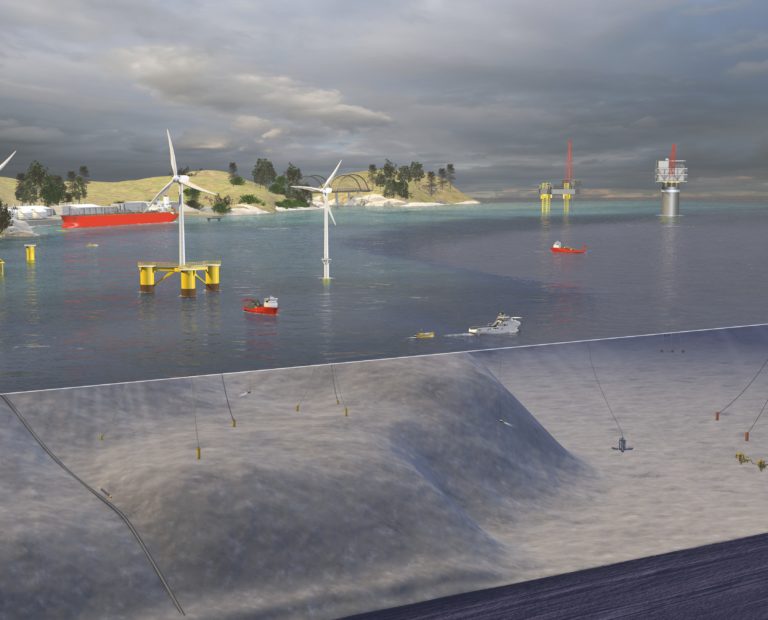

When choosing a seafloor drilling solution, it is important to have data quality at front of mind. A proven track record of acquiring high-quality data for a wide variety of projects can also be beneficial, including things like site investigations for jack-up and fixed platform foundations, floating production storage and offloading (FPSO) anchor spreads, and subsea structures and pipelines.

The advantage of using a portable remotely operated seafloor-based drilling system is that the drill unit is located on the seabed, decoupled from vessel motions, providing a highly stable and controlled platform, enabling geotechnical teams to make precise adjustments as changes in geologies occur and collect extremely accurate data.

It is equally as important to consider the environmental impact of your operations. The most eco-friendly solutions are designed to produce minimal disturbance to the seabed and deliver undisturbed samples from the mudline, with borehole depth accuracy.

2. SAFELY MITIGATE THE CHALLENGES OF ULTRA-DEEP-WATER OPERATIONS

Ultra-deep-water operations present unique and complex challenges including harsh metocean conditions and soft sediments with low shear strengths at the mudline.

When operating in extreme environments it is important to select a seabed testing method that has accurate sensors which will enable engineers to keep the unit vertical even on sloping or undulating surfaces. Extremely soft sediments can easily be disturbed when a system lands on the seabed, which can affect the quality and depth accuracy of the sample. Choosing a drill that can land on very soft sediments without penetrating the seabed will guarantee that data gathering commences at the undisturbed mudline.

When choosing between a remotely operated seabed drilling system and a drillship, considerations should be made around weather operability and whether the unit can work in sea states that may impact data quality and safety.

3. MAXIMUM PRODUCTIVITY RESULTING IN COST SAVINGS

Operators’ common goal is to execute a safe, successful project on time and within budget. Vessel days and personnel on board (POB) are major contributors to overall project footprint and cost which is why operators should consider alternative methodologies to keep these to a minimum. Choosing a remotely operated seabed drilling system instead of a drillship in deep water can increase productivity fivefold by operating directly on the seabed, avoiding time-consuming deployment of the drill string, yielding immediate efficiency gains in deep water.

Switching dynamically between drilling and testing tools in a single deployment or a single hole allows penetration of a wide range of soils and delivers a variety of samples, from hard rock to soft sediments, without the need to recover the drill module to the vessel.

Safety is also a major consideration when selecting a geotechnical solution. Deploying a system with an umbilical and controlling it remotely by computer limits human interaction with heavy, mechanical equipment. This eliminates the need to manipulate pipe sections on the deck, a leading cause of accidents.

4. PROTECT THE ENVIRONMENT WHILE COLLECTING HIGH-QUALITY DATA

We understand that operators have environmental goals to meet, especially when working in deep water where marine life is prevalent. We recommend considering options to minimise noise pollution and utilise biodegradable hydraulic and environmentally considerate drilling fluids. A remotely operated seabed drill is less invasive than a drillship and will pose minimal disturbance to the seabed and deliver undisturbed samples from the mudline, with a borehole depth accuracy of 25mm.

5. CONSIDER THE COMPLETE SOLUTION

Reduce interfaces, project costs, and save time by sourcing a provider who can deliver a complete solution, from site investigation planning, data gathering and sample testing, to data integration, interpretation, and foundation design. A turnkey solution will ensure that following a successful geotechnical campaign offshore, the same team will coordinate sample transportation to a local in-house advanced testing laboratory before the full data interpretation reports are then presented on completion. Minimising interfaces not only saves time but guarantees that the same team are dealing with the project from start to finish which eliminates the risk of loss of data accuracy.

THE ACTEON SOLUTION

At Acteon, our focus is on helping customers to reduce project risks by providing accurate data and understanding of the seabed combined with continuous monitoring to enable life-cycle assessments. We have extensive experience in delivering high-quality geophysical and geotechnical surveys in challenging seabed conditions to ensure that customers have a clear understanding of seafloor structure and composition. 7o+ geotechnical site investigations have been completed by Acteon; more than anyone else globally.

A history of product innovation increases the quality of data collected in the most efficient, and safest manner. Our sampling and testing capabilities are delivered using recognised brands and proven in-house technologies, including our unique PROD seabed drilling systems, which can switch between piston sampling, rotary coring and in situ testing to maximise productivity, and shallow soil investigation and sampling through the GeoROV system. Sampling activities are backed up by our in-house technology centre and a geotechnical laboratory that conducts geoscience research and development.

Benthic’s technology center and geotechnical laboratory located in the Technological Park of the Federal University of Rio de Janeiro – Brazil.

GEO-SERVICES BROCHURE

Discover more about our solutions to real customer challenges and explore our full range of services to help you achieve project efficiencies.