Manufacturing enough fit-for-purpose units for the mobilisation date

With a non-negotiable deadline, it is important to put control measures in place to ensure that it is met. In this case, Canopus and Ramses units needed to be manufactured specifically for the project, but UTEC would revert to a conventional spread if either quantity or capability were not ready by a key date.

During the manufacture and assembly phases in the lead up to mobilisation, UTEC and iXblue had regular meetings to monitor progress and define the specification for the equipment to meet project requirements. Additional features necessary for the project scope of work were tested by iXblue and witnessed by UTEC.

Controlling the risk of design/manufacturing flaws

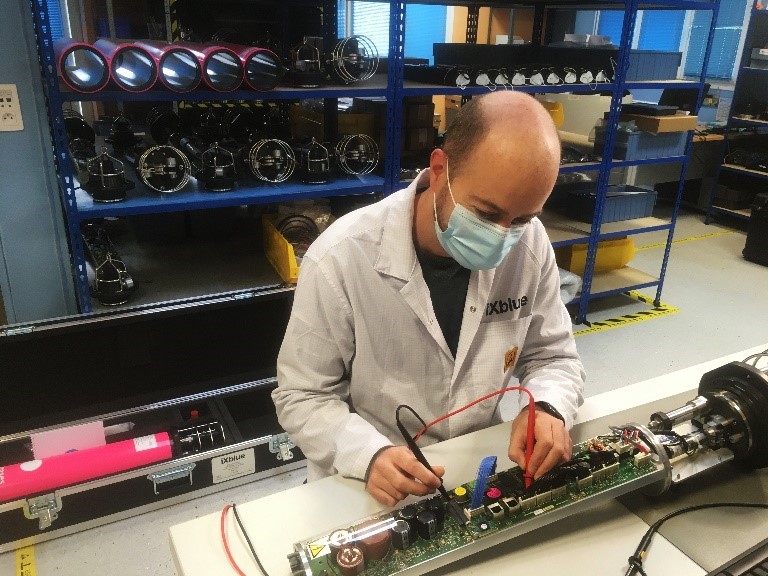

UTEC audited iXblue’s design and testing processes for key components such as the pressure housing, transducer, and battery packs (inclusive of a review of test reports). UTEC was able to audit iXblue’s manufacturing and testing process at their factory to the requirements of ISO 9001:2015 Sect 8.3. The audit was completed remotely due to COVID-19 travel and quarantine restrictions.

The control measure for manufacturing flaws was pre-mobilisation testing which was completed at the same time as iXblue’s factory acceptance testing (FAT). This testing had to be delivered remotely, again due to restrictions preventing UTEC technicians from travelling to the factory, and COVID-related delays shipping the units to UTEC’s workshops beyond the mobilisation date.

APPLYING THE EXPERTISE OF ADVANCED SYSTEMS ENGINEERS

A key aspect of successful first use of new technology is the expertise of the offshore personnel.

The training was provided remotely by iXblue a few weeks before the personnel’s mobilisation date so their learnings would still be fresh in their minds.

Although at the time, the classroom training wasn’t permitted, field staff engagement was achieved by getting some of the system hardware into a UTEC workshop for personnel to have hands-on experience in connecting and testing the equipment.

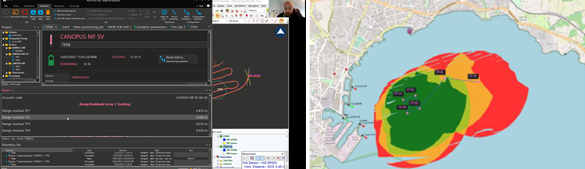

Technical support to the field personnel continued into the offshore phase on two fronts; an iXblue technician was onboard the construction vessel to work with the UTEC field staff on deploying and using the system, and a remote-control link over the vessel VSAT was set up so that the iXblue system developers could configure and control their systems even when mounted on an ROV working at the seabed. Fortunately, due to the training, preparation and involvement of the field staff, the link was not needed. However, experience in set-up and tests of the link proved that such a link could be used in future projects permitting a reduction in offshore personnel.

DELIVERING A SUCCESSFUL OUTCOME

Through leveraging strategic partnerships and applying the expertise of systems engineers, UTEC was able to bring disruptive new technology to market. The team involved now have the expertise to apply this technology to other customers’ projects, giving them the opportunity to achieve the same commercial benefits.

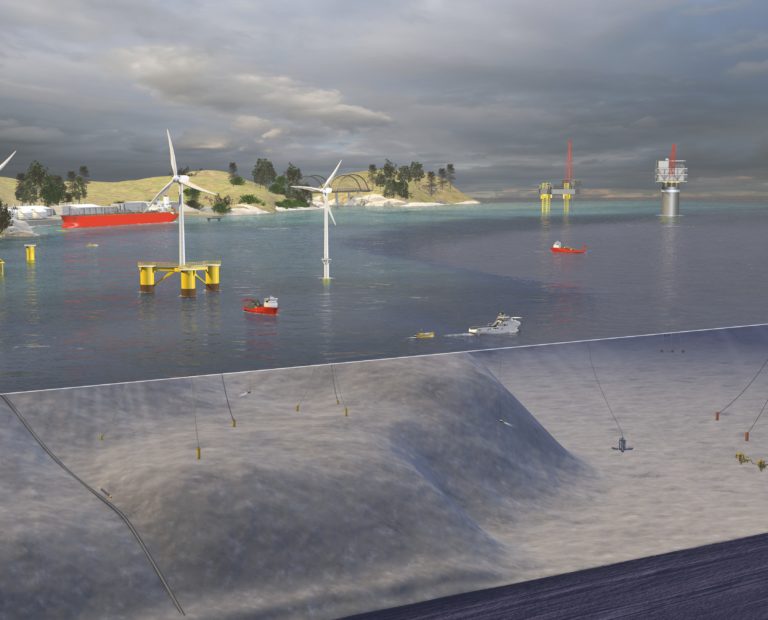

The collaboration between UTEC and iXblue led to the successful first use of Canopus and Ramses as a sparse positioning system for the development of an FLNG (floating liquefied natural gas) project off the East coast of Africa.

UTEC has benefited by developing first-use strategies and execution of other new systems, and iXblue has used the field personnel feedback to improve the system ready for second users and beyond.

GEO-SERVICES BROCHURE

Discover more about our solutions to real customer challenges and explore our full range of services to help you achieve project efficiencies.