How to achieve a successful slot recovery

Asset owners in the Middle East demand quick, safe, and cost-effective slot recovery projects. The key to achieving a successful outcome is to have facilities, local crew and high quality regularly maintained equipment available to call off from local facilities, all supported by pre-planning and engineering.

Claxton, a Cutting and Decommissioning brand in Acteon’s Energy Services division, has developed bespoke solutions to tackle the challenges associated with slot recovery operations in the Middle East. Claxton applies its extensive track experience record in this region and locally based crew and assets with engineering competence to meet the market demands.

How bespoke tooling can be used

With the industry’s drive for operations to become more efficient, Claxton has developed systems that combine two tools to enable the recovered conductor to be drilled and cut at the same time. This all-electric tool reduces the combined cut and pin time from one and half hours to thirty minutes.

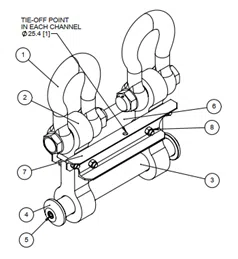

To address the space limitations of rotary tables, Claxton has also developed internal lifting equipment which is proven to lift the weight of the well configuration through the restricted opening of the rotary table. Without this equipment, the asset owner would have to request an additional fishing/casing company to provide many sizes of ‘casing spears’ to spear the innermost casing and retrieve it to the rig floor.

The conductor deflector tool is another example where Claxton has developed a bespoke solution to enable new wells from existing infrastructure. The tool is used to absorb the lateral forces of a new conductor being deflected without adding these forces to the platform structure.

Wealth of experience

Since 2010 Claxton has been successfully performing conductor recovery operations in the Arabian Gulf. Each conductor recovery is different due to missing records, level of corrosion, platform design, or lack of rig space, which has enabled Claxton to develop a variety of innovative methodologies to address the challenges outlined in this blog.

How to start planning your project

Based on Claxton’s project experience, early engagement with the relevant parties ensures that the challenges of the recovery situation are fully understood, and operator deliverables are met in a safe, efficient, and cost-effective manner.

DRILLING AND DECOMMISSIONING SERVICES - REQUEST MORE INFORMATION

Acteon’s expertise in drilling and decommissioning spans decades and covers the full lifecycle of a project from the acquisition of subsea information and data, to bespoke drilling packages to onshore disposal and recycling.