SMALL BUT MIGHTY

The development of marine growth’s colonising organisms can lead to the rapid decline of asset integrity. In the case of metallic materials, undesirable changes in material properties due to biofilm are referred to as biocorrosion. Biocorrosion results in billions of dollars in damages each year in the United States alone, and the growth of marine life will eventually lead to visible cracks and dents within assets, resulting in inefficiencies for operators.

The challenges of marine growth

Not only does marine growth thickness affect dimensional measurements of ageing structures, but it can cause handling issues when replacing existing parts due to additional weight. For example, in The Offshore Renewable Energy Catapult’s Marine Growth Mapping and Monitoring, wave energy devices located on the Irish west coast had an increased structural mass of over 10% thanks to marine growth.

Then, when these aged assets face decommissioning, contractors must combat with constraints in managing the disposal of the assets that have marine growth. According to Oil and Gas UK’s report, The Management of Marine Growth During Decommissioning, finding landfill facilities that are sufficiently close and are willing to accept marine growth is a huge challenge for decommissioning contractors. On the evidence of interviews within the report, none of the UK contractors was able to compost their marine growth.

FOUR OPTIONS FOR PREVENTIONS, PRECAUTIONS AND ALTERNATIVES

Although it is impossible to completely thwart the natural causes of biofouling, there are preventive measures and efforts that can be taken to preserve asset integrity:

-

In-water cleaning and preventive chemicals

In-water cleaning can be carried out during a Remotely Operated Vehicle (ROV) inspection, with an onboard cleaning kit that enables the clearing of marine growth and corrosion scale. This can be achieved with high-pressure jets, but for large areas and equipment, can be time-consuming and costly.

Sodium hypochlorite is a simple solution that has been effectively used in the oil and gas industry for years and is perhaps the most efficient and viable solution to the industry’s biofouling woes. The process only requires three essential ingredients – water, salt and electricity.

How Acteon can help: The marine growth removal system provided by Claxton, a cutting and decommissioning brand in Acteon’s Energy Services division, can remove both hard and soft fouling, subsea and topside. The systems are commonly required for cleaning monopiles for offshore wind farms, prior to the installation and grouting of the transition piece. Claxton’s marine growth removal systems use high-pressure water pumps to supply the manipulators with water to remove fouling.

The marine growth removal tool from Claxton

-

Antifouling coatings

Antifouling technology can reduce the detriments of marine growth, including coating and paint that are effective for both offshore oil and gas rigs and ships. The application of such coatings improves the durability and overall performance of assets, with the coating acting as a barrier against corrosion that will degrade and weaken the metal.

High demand for antifouling coatings from the shipping industry is expected to drive the growth of the market, claims a report by Markets and Markets, which projects the market to grow from $5.61 billion in 2015 to $9.22 billion by 2021.

How Acteon can help: Many components manufactured by Acteon companies come with the option to add a variety of anti-corrosive claddings. As an example, Probe’s API 6A flanges are available with corrosion-resistant properties which are suitable to withstand the harshest subsea environments.

A manifold block with corrosion-resistant inlay manufactured by Probe

-

Accurate risk assessments

Strong risk-assessment measures can save operators money in the long run when dealing with all the elements that relate to ageing assets – and the multitude of issues that cause them, enabling inspectors to spot the health and safety risks and costs caused by biofouling before they become a larger issue.

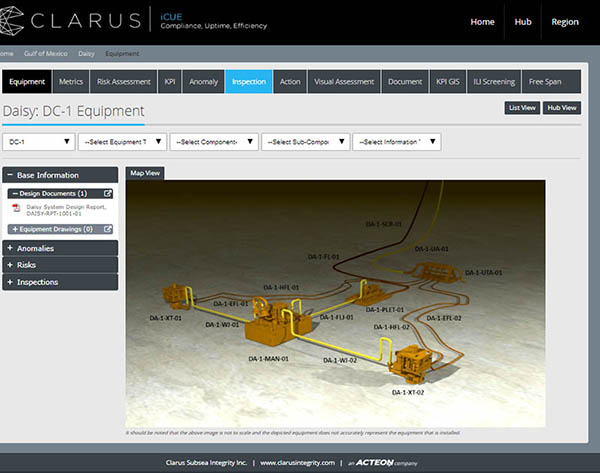

How Acteon can help: We can provide accurate risk-based inspection planning. Clarus’ approach uses component-specific inspection checklists and datasheets which are developed with an aim to gather relevant equipment condition data. The goal is to provide clear information about condition and performance capabilities of offshore assets so that appropriate preventive measures against biofouling and other integrity threats can be taken.

A screenshot of the Clarus iCue system performing risk based inspection planning

-

Rig to Reef – an alternative to removing and preventing marine growth

Rig-to-reef (RTR) is the practice of converting decommissioned platform infrastructure into artificial reefs for the seabed and is a strong alternative when decommissioning a rig to support a great diversity of marine life. The pros appear to outweigh the cons of choosing RTR when decommissioning a rig, which proves to be popular with sea life over their 20-30-year life span. The legislation of the region will be the deciding factor as to whether a rig can be converted into a reef. In California, offshore companies could be required to fund a state-mandated rigs-to-reefs program, showing a growing trend within the industry.

How Acteon can help: Acteon, we have several solutions to extend the lifetime of your ageing assets anywhere in the world. From slot recovery to retrofit centralizers, we can help assess, prepare and install products into your existing platforms to extend the life of your assets.

A retrofit centralizer which was designed and installed by Claxton

SUSTAINABLE SOLUTIONS FOR ASSET LONGEVITY ACROSS ENERGY INDUSTRIES

As we have highlighted in this blog, Acteon leverages its wealth of design and construction experience from its operating companies to provide survey, monitoring, engineering and remediation services into the oil and gas and renewables sectors to ensure the safe, efficient long-term operations of clients’ assets. Our single contact and contract eliminate the need to manage separate interfaces allowing the opportunity to gather asset condition data combined with engineering assessment to provide efficient remediation and life extension solutions through a simple ‘acquire, assess, act’ process.

ASSET INTEGRITY AND LIFE EXTENSION BROCHURE

Increase returns by safely and cost-effectively maintaining reliability beyond original design limits.