Search resources

Filter by Specialisms

Filter by Brands

Filter by Specialisms

Filter by Brands

Filter by Specialisms

Filter by Brands

Filter by Specialisms

Filter by Brands

Filter by Specialisms

Filter by Brands

Filter by Specialisms

Filter by Brands

Filter by Specialisms

Filter by Brands

Filter by Specialisms

Filter by Brands

Filter by Specialisms

Filter by Brands

Filter by Specialisms

Filter by Brands

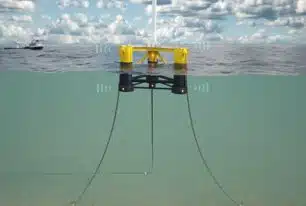

Marine foundations:

AllShowing 1-12 of 81

Marine foundations:

AllPremium only

Sort by